TM-9-2320-361-20 - Page 143 of 1207

TM 9-2320-361-20

Table 2-3. Compressed Air and Brake System Troubleshooting (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4. EXCESSIVE PEDAL PRESSURE REQUIRED TO STOP VEHICLE (BRAKE PEDAL STOPS TWO INCHES OR

MORE ABOVE FLOORBOARD); NO APPARENT AIR SYSTEM FAILURE

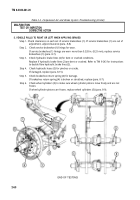

Step 1. Check service brakeshoe (1) linings for oil or grease contamination.

If service brakeshoe (1) linings are saturated with oil or grease, repair oil or grease leak

and replace brakeshoes (para. 8-7).

Step 2. Direct assistant to apply service brakes and listen for evidence of air escaping at air-

hydraulic cylinder (2) and at vent (5).

a. If escaping air is present, replace air-hydraulic cylinder (para. 8-11).

b. If no air is escaping, proceed to test 1.

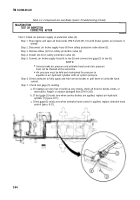

Test 1. Check air-hydraulic cylinder (2) for proper delivery line (7) supply pressure.

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Step 7.

Step 8.

Stop engine and open all draincocks (TM 9-2320-361-10) until brake system air pressure is

vented.

Remove two screws (3) and shield (4) from air-hydraulic cylinder (2).

Disconnect delivery line (7) from elbow (6).

Remove elbow (6) from air-hydraulic cylinder (2).

Install tee (9) on air-hydraulic cylinder (2).

Connect test gage (8) to tee (9) and connect delivery line (7) to tee (9).

Direct assistant to start engine (TM 9-2320-361-10) and allow air pressure to build to

normal operating pressure.

Check test gage (8) reading and compare with reading on instrument panel air pressure

gage.

NOTE

Air pressure gage in instrument panel has a maximum pressure

scale of 120 psi. If old governor has been replaced with new

a.

b.

governor, air pressure may exceed maximum pressure reading on

instrument panel gage.

If reading on test gage (8) is same as instrument panel air pressure gage, replace air-

hydraulic cylinder (2) (para. 8-11).

If reading on test gage (8) is less than instrument panel air pressure gage, check

delivery line (7) for restrictions. If delivery line (7) is damaged or restricted, replace

(para. 8-15).

2-58

Back to Top