TM-9-2320-361-20 - Page 147 of 1207

TM 9-2320-361-20

Table 2-3. Compressed Air and Brake System Troubleshooting (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

7. BRAKES SQUEAL

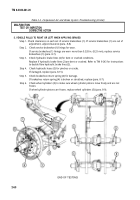

Step 1. Check service brakeshoes (1) for proper installation, glazing, distortion, or excessive wear.

a. If service brakeshoes (1) are improperly installed, replace (para. 8-7).

b. If service brakeshoes (1) are glazed, distorted, or worn more than 0.328 in. (8.33 mm),

replace (para. 8-7).

Step 2. Check brakedrums (2) for heat spotting or heavy scoring.

If brakedrums (2) are heat-spotted or scored more than 0.03 in. (0.76 mm), replace

(paras. 9-3 and 9-4).

Step 3. Check brakedrum (2) and hub (4) for proper assembly.

If brakedrum (2) and hub (4) are not properly assembled, or if any screws (3) are missing,

replace (para. 9-3 or 9-4).

COMPRESSED AIR

WARNIN G

Do not disconnect air lines before draining air reservoirs. Small

parts under pressure may shoot out with high velocity, causing

injury to personnel.

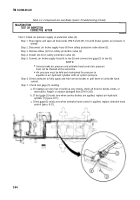

8. EXCESSIVE PEDAL PRESSURE REQUIRED TO STOP VEHICLE WHEN TOWING A TRAILER (M275A2)

Step 1. Start engine (TM 9-2320-361-10) and allow air pressure to build to normal operating pressure with

trailer air lines disconnected from trailer and connected to dummy coupling and airbrake valves open.

Step 2. Check lines, hoses, and rubber gaskets (10) for leaks.

Step 3. Direct assistant to fully apply service brakes or pull down on trailer airbrake hand control.

a. If air leaks are found, repair as required.

b. If no air leaks are found, perform test 1.

NOTE

Perform test 1 on both trailer brake supply hoses.

Test 1. Check trailer brake supply hose (6) for proper pressure.

Step 1. Stop engine and open all draincocks (TM 9-2320-361-10) until brake system air pressure is

vented.

Step 2. Remove quick-disconnect coupling (5) from trailer brake supply hose (6).

2-62

Back to Top