TM-9-2320-361-20 - Page 155 of 1207

TM 9-2320-361-20

Table 2-3. Compressed Air and Brake System Troubleshooting (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

12. LOW OR NO READING ON AIR PRESSURE GAGE AND WARNING BUZZER SHUTS OFF

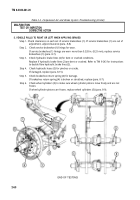

Test 1. Check air supply pressure to air pressure gage (1).

13.

Step 1. Stop engine and open all draincocks (TM 9-2320-361-10) until brake system air pressure is

vented.

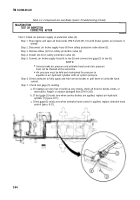

Step 2. Disconnect air supply line (2) from air pressure gage adapter (3).

Step 3. Connect air supply line (2) to test gage (4).

Step 4. Start engine (TM 9-2320-361-10) and allow air pressure to build to normal operating

pressure.

Step 5. Check test gage (4) reading.

a.

b.

If reading is low or zero, check air supply line (2) for bends, kinks, or leaks. Repair or

replace air supply line if bent, kinked, or leaking (para. 8-15).

NOTE

Air pressure gage on instrument panel has a maximum pressure

scale of 120 psi. If old governor has been replaced with new

governor, air pressure may exceed maximum pressure reading on

instrument panel gage.

If reading is above 85 psi (586 kPa) on test gage (4), replace air pressure gage (1)

(para. 4-11).

END OF TESTING!

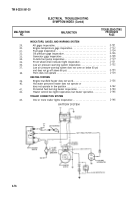

WARNING BUZZER FAILS TO SOUND ON LOW PRESSURE (BELOW 60 PSI)

Refer to electrical troubleshooting table 2-4.

2-70

Back to Top