TM-9-2320-361-20 - Page 162 of 1207

TM 9-2320-361-20

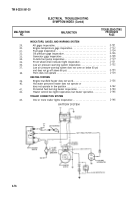

Table 2-4. Electrical Troubleshooting.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

BATTERY SYSTEM

1. ALL VEHICLE ELECTRICAL SYSTEMS INOPERATIVE

WARNIN G

Battery acid (electrolyte) is extremely harmful. Always wear safety goggles

and rubber gloves when performing battery maintenance. Severe injury

will result if acid contacts eyes or skin.

Do not smoke, have open flame, or make sparks when performing battery

maintenance. Batteries may explode causing severe injury to personnel.

Remove all jewelry such as rings, dog tags, bracelets, etc. If jewelry or

disconnected battery ground cable contacts battery positive post, a direct

short can result, causing damage to equipment or severe injury to personnel.

When removing battery cables, disconnect ground cable first. Do not allow

tools to come in contact with vehicle when disconnecting cable clamps. A

direct short can result, causing instant heating of tools, tool damage,

battery damage, or battery explosion, and severe injury to personnel.

CAUTION

During installation of battery terminals, ensure positive clamps are

installed on positive (+) posts and negative clamps are installed on

negative (-) posts. Failure to connect clamps to correct posts will reverse

polarity of circuitry and may cause damage to rectifier diodes in

alternator, vehicle wiring, and radios (if equipped).

Do not use a hammer during installation of battery terminal. Spread

battery terminal open, or damage to equipment may result.

Step 1. Open door of battery compartment. Loosen two thumbscrews and slide batteries onto

running board. Visually check connections of battery cables.

Ensure battery cables are correctly connected to batteries (para. 4-48).

Step 2. Visually check batteries for cracks and leaks. Check terminal posts for corrosion and

breaks (TM 9-6140-200-14).

a.

b.

c.

Replace any battery that is cracked, leaking, or has broken terminal posts (para. 4-49).

If terminal posts or cable clamps are corroded, use soda and water solution to neutralize

battery acid. Remove battery ground cable no. 7 from negative post first. Remove cable

clamps from battery posts, clean posts, and clamp mating surfaces to bright metal.

If battery terminals are clean and malfunction still exists, go to test 1.

2-77

Back to Top