TM-9-2320-361-20 - Page 163 of 1207

TM 9-2320-361-20

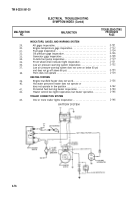

Table 2-4. Electrical Troubleshooting (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Test 1. Check specific gravity of each cell before adding distilled water.

Step 1. Using optical battery tester, which requires no temperature compensation, check specific

gravity of electrolyte in each cell (TM 9-6140-200-14).

If specific gravity of any cell is below 1.225, battery must be replaced or recharged. Add distilled

water as necessary after checking battery. Charge battery as necessary (TM 9-6140-200-14).

Step 2. Check specific gravity of cells after battery has been charged (TM 9-6140-200-14).

a. If specific gravity of any cell does not increase to 1.280 (full charge) in 25 hours of

charging, replace battery (para. 4-49).

b. Each cell in a battery must test within 0.025 points of each other. If specific gravity of

any cell is lower than 1.255 [corrected to 80°F (27°C) if necessary] after 25 hours of

charging, replace battery (para. 4-49).

Test 2. Disconnect battery ground cable (para. 4-48) and test battery cables as follows:

Step 1. Set multimeter to RX1 scale.

Step 2. Check for continuity of battery cables no. 6 and 68 and for worn or frayed insulation.

a. If resistance is greater than 1 ohm, replace or repair battery cables (para. 4-48 or 4-51).

b. If insulation is worn or frayed, replace or repair battery cables (para. 4-48 or 4-51).

Step 3. Check continuity of battery ground cable no. 7 to frame ground.

a. If resistance measures greater than 1 ohm, clean cable no, 7 connection at right-hand

frame rail.

b. If continuity is still greater than 1 ohm, replace or repair battery cable (para. 4-48 or 4-51).

Step 4. Connect battery ground cable (para. 4-48) and proceed to test 3.

Test 3. Check for battery voltage at starter solenoid.

Step 1. Set multimeter to a voltage range that will measure 24 Vdc.

Step 2. Check lead no. 6 at contact 2 of starter solenoid for battery voltage.

If battery voltage is not present, clean connections of lead no. 6 at contact no. 2 of starter solenoid.

2-78

Back to Top