TM-9-2320-361-20 - Page 171 of 1207

TM 9-2320-361-20

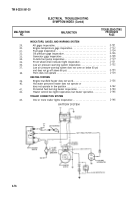

Table 2-4. Electrical Troubleshooting (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. STARTER MOTOR OPERATES, BUT ENGINE CRANKS SLOWLY

NOTE

Test 1.

Test 2.

If STE/ICE is available, perform NG80 - starter circuit tests

(chapter 2, section VII).

Check batteries for overheating by cranking engine for 15 seconds and feeling battery

terminal connections.

If battery terminal is hot, a loose or corroded connection is indicated.

a. Clean corroded connection to bright metal.

b. Tighten all loose connections at batteries, ground, and starter.

Test specific gravity for each battery.

Perform a specific gravity test (TM 9-6140-200-14), Batteries must test 1.255 or greater,

temperature corrected, and each cell in a battery must test within 0.025 points of the others.

a. Charge all batteries not meeting requirements (TM 9-6140-200-14) and check specific

gravity again.

b. If 0.025 point variation still exists within any battery, it is defective and must be

replaced (para. 4-49).

Test starter motor voltage.

Test 3.

Step 1. Set multimeter to a voltage range that will measure 24 Vdc.

Step 2. Connect multimeter positive lead to positive terminal lug 6 of starter motor and negative

lead to terminal lug 5 on end plate of starter motor.

Step 3. Crank engine (TM 9-2320-361-10) and observe cranking voltage on multimeter. Voltage

should exceed 19 Vdc.

If voltage is less than 19 Vdc, clean and tighten starter motor connections.

Test 4. Test starter motor-to-solenoid strap voltage drop.

Step 1. Set multimeter to a voltage range that will measure tenths of a volt.

Step 2. Connect multimeter negative lead to positive terminal lug 6 of starter motor and

multimeter positive lead to starter motor solenoid terminal lug 3.

Step 3. Crank engine (TM 9-2320-361-10) and observe multimeter. A voltage reading exceeding 0.2

volts indicates a bad connection at starter motor terminal lug 3 and terminal lug 6 of solenoid.

Clean and tighten connections.

Test 5. Test starter motor solenoid contact voltage drop.

Step 1. Set multimeter to a voltage range that will measure tenths of a volt.

Step 2. Connect multimeter between starter motor solenoid terminal lugs 3 and 2.

Step 3. Crank engine (TM 9-2320-361-10) and observe multimeter. A voltage reading exceeding 0.4

volts indicates a defective starter motor solenoid.

a. Replace starter motor and solenoid assembly (para. 4-7).

b. If malfunction still exists, go to tests 6, 7, and 8.

Test 6. Test negative cable 7 voltage drop from batteries to starter motor.

Step 1.

Step 2.

Step 3.

Set multimeter to voltage range that will measure tenths of a volt.

Connect multimeter positive lead to terminal stud on end plate of starter motor and

negative lead to frame ground.

Crank engine (TM 9-2320-361-10) and observe multimeter. A voltage reading exceeding 0.4

volts indicates a defective starter motor solenoid.

a. Replace starter motor and solenoid assembly (para. 4-7).

b. If malfunction still exists, go to tests 7 and 8.

2-86

Back to Top