TM-9-2320-361-20 - Page 153 of 1207

TM 9-2320-361-20

Table 2-3. Compressed Air and Brake System Troubleshooting (Contd).

MALFUNCTION

TEST

OR INSPECTION

CORRECTIVE ACTION

10. AIR PRESSURE DOES NOT BUILD UP TO NORMAL OPERATING PRESSURE (ABOVE 85 PSI) ACCORDING

TO GAGE

11.

Step 1. Check for compressed air leaks.

If leakage is found, repair or replace compressed air lines or fittings (TM 9-243).

Step 2. Adjust air governor (para. 8-29).

Step 3. Perform test 2 of malfunction 9.

END OF TESTING!

NOTE

Air pressure gage on instrument panel has a maximum pressure

scale of 120 psi. If old governor has been replaced with new

governor, air pressure may exceed maximum pressure reading on

instrument panel gage.

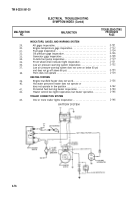

AIR PRESSURE EXCEEDS

MAXIMUM (GAGE READS OVER 120 PSI) AND SAFETY VALVE OPENS TO

RELEASE PRESSURE

Step 1.

Step 2.

Step 3.

Check for air loss through accessories (refer to malfunctions 14, 15, and 16).

NOTE

Step 2 applies to M275A2 only.

Check for excessive air pressure as indicated by instrument panel gage.

If air pressure exceeds maximum and safety valve opens to release pressure, replace air

governor (para. 8-29.

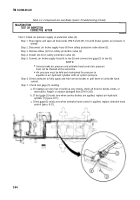

Check governor signal line (4) for crimps, bends, or leaks.

a. If governor signal line (4) is crimped, bent, or leaking, repair or replace governor signal

line (4) (para. 8-15).

b. If no restrictions are apparent, proceed to test 1.

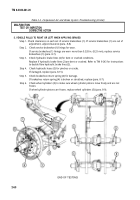

Test 1. Check governor signal line (4) pressure.

Step 1.

Step 2.

Step 3.

Step 4.

Step 5.

Step 6.

Stop engine and open all draincocks (TM 9-2320-361-10) until brake system air pressure is

vented.

Disconnect governor signal line (4) from adapter (3).

Remove adapter (3) from air governor (2).

Install tee (5) on air governor (2).

Connect test gage (1) to tee (5) and governor signal line (4) to tee (5).

Direct assistant to start engine (TM 9-2320-361-10) and allow air supply to built to normal

operating pressure.

2-68

Back to Top