TM-9-2320-361-20 - Page 148 of 1207

TM 9-2320-361-20

Table 2-3. Compressed Air and Brake System Troubleshooting (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

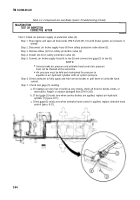

Step 3. Install adapter (7) in trailer brake supply hose (6).

Step 4. Connect test gage (8) to adapter (7).

Step 5. Direct assistant to start engine (TM 9-2320-361-10) and allow air supply to build to normal

operating pressure.

NOTE

●

Service brake air pressure and airbrake hand control air pressure

must not be checked at the same time.

●

Air pressure must be held and maintained for pressure to

equalize in air-hydraulic cylinder with air system pressure.

Step 6. Direct assistant to fully apply and hold service brakes or pull down on trailer airbrake

hand control (TM 9-2320-361-10).

Step 7. Check test gage (8) reading and compare with reading on instrument panel gage.

a.

b.

NOTE

Air pressure gage on instrument panel has a maximum pressure

scale of 120 psi. If old governor has been replaced with new

governor, air pressure may exceed maximum pressure reading on

instrument panel gage.

If reading is lower than instrument panel gage reading, perform test 2.

If reading compares with instrument panel gage, check trailer brake system for proper

operation (TM 9-2320-213-14).

Step 8. Reinstall quick-disconnect coupling (5).

a.

b.

c.

d.

e.

Disconnect test gage (8) from adapter (7).

Remove adapter (7) from trailer brake supply hose (6).

Install quick-disconnect coupling (5) to trailer brake supply hose (6).

Close all airbrake valves (TM 9-2320-361-10).

Start engine (TM 9-2320-361-10) and ensure airbrake system pressurizes to normal

operating pressure

2-63

Back to Top