TM-9-2320-361-20 - Page 635 of 1207

TM 9-2320-361-20

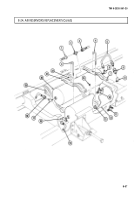

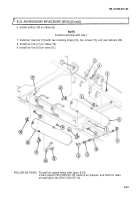

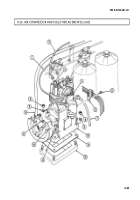

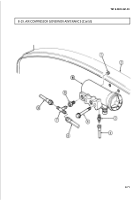

8-26. AIR COMPRESSOR AND PULLEY REPLACEMENT

This task covers:

a. Removal

c. Assembly

b. Disassembly

d. Installation

INITIAL SETUP:

APPLICABLE MODELS

All

MATERIALS/PARTS

Three gaskets

Eight lockwashers

Antiseize tape (Appendix C, Item 27)

Cap and plug set (Appendix C, Item 8)

REFERENCES (TM)

TM 9-2320-361-10

TM 9-2320-361-20P

EQUIPMENT CONDITION

Air reservoir drained (TM 9-2320-361-10).

Air compressor drivebelt removed (para. 8-28).

GENERAL SAFETY INSTRUCTIONS

Do not disconnect air lines before draining air

reservoirs.

Allow air compressor to cool before handling.

a. Removal

1.

2.

3.

4.

5.

6.

7.

8.

9.

WARNIN G

Do not disconnect air lines before draining air reservoirs. Small

parts under pressure may shoot out with high velocity, causing

injury to personnel.

Air compressor becomes hot during operation. Allow compressor

to cool before handling, or injury to personnel may result.

NOTE

Plug air lines as they are disconnected.

Remove air line (7) from adapter (4).

NOTE

On some air compressors, the air governor air line is on front of

compressor near pulley.

Remove air governor air line (2) from elbow (3).

Remove screw (14), clamp (13), and fuel pump return line (1) from air compressor (10). Tie fuel

pump return line (1) out of way.

Install screw (14) in air compressor (10).

Remove screw (5) and bracket (6) from air compressor (10).

Install screw (5) in air compressor (10).

Remove four nuts (8), lockwashers (9), and bracket (15) from base of air compressor (10). Discard

lockwashers (9).

Tie tachometer cable (16) and bracket (15) out of way.

Remove air compressor (10) and gasket (11) from air compressor support (12). Discard gasket (11).

8-62

Back to Top