TM-9-2320-361-20 - Page 639 of 1207

TM 9-2320-361-20

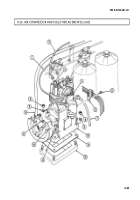

8-27. AIR COMPRESSOR SERVICING

This task covers:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning

INITIAL SETUP:

APPLICABLE MODELS

All

MATERIALS/PARTS

Gasket

Two lockwashers

Drycleaning solvent (Appendix C, Item 26)

REFERENCES (TM)

TM 9-2320-361-10

TM 9-2320-361-20P

EQUIPMENT CONDITION

Parking brake set (TM 9-2320-361-10).

Hood raised and left side panel down

(TM 9-2320-361-10).

GENERAL SAFETY INSTRUCTIONS

Keep fire extinguisher nearby when using

drycleaning solvent.

Compressed air source will not exceed 30 psi

(207 kPa).

Eyeshields must be worn when cleaning with

compressed air.

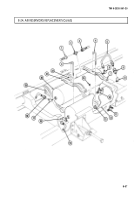

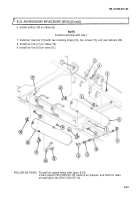

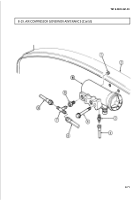

1. Loosen two screws (5) on intake air cleaner (2).

2. Remove two screws (4), lockwashers (3), intake air cleaner (2), and gasket (1) from air compressor

(6). Discard lockwashers (3) and

gasket (1).

b. Disassembly

1. Remove two screws (5) from intake air cleaner (2).

2. Remove cap (10), spring (9), plate (8), and filter (7) from body of intake air cleaner (2).

c. Cleaning

WARNING

Drycleaning solvent is flammable and will not be used near open

flame. Use only in well-ventilated places. Failure to do so may

result in injury to personnel.

Compressed air source will not exceed 30 psi (207 kPa). When

cleaning with compressed air, eyeshields must be worn. Failure

to wear eyeshields may result in injury to personnel.

1. Wash filter (7) in drycleaning solvent.

2. Using compressed air source, clean and dry filter (7).

d. Assembly

1. Install filter (7), plate (8), and spring (9) in body of intake air cleaner (2).

2. Install cap (10) on intake air cleaner (2) with two screws (5), Tighten screws (5) finger tight.

8-66

Back to Top