TM-9-2320-361-20 - Page 641 of 1207

TM 9-2320-361-20

8-28. AIR COMPRESSOR DRIVEBELT REPLACEMENT

This task covers:

a. Removal

c. Adjustment

b. Installation

INITIAL

SETUP:

APPLICABLE MODELS

REFERENCES (TM)

All

TM 9-2320-361-10

SPECIAL TOOLS

Air compressor pulley spanner wrench

(NSN 5120-00-070-7809)

MATERIALS/PARTS

Two lockwashers

TM 9-2320-361-20P

EQUIPMENT CONDITION

Parking brake set (TM 9-2320-361-10).

Hood raised and secured (TM 9-2320-361-10).

Alternator belts removed (para. 4-2).

Radiator removed (para. 3-42).

GENERAL SAFETY INSTRUCTIONS

Ensure fuel shutoff valve is OFF before tuning

over engine.

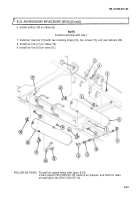

1. Remove twoscrews (2) and lockwashers (1) from adjustable pulley flange (4). Discard

lockwashers (1).

2. Using puller wrench and holding pulley flange (3), turn adjustable pulley flange (4)

counterclockwise to loosen drivebelt (5).

3. Remove drivebelt (5) from crankshaft pulley (7), pulley flange (3), and adustable pulley flange (4).

b. Installation

1. Place drivebelt (5) between pulley flange (3) and adjustable pulley flange (4) and on crankshaft

pulley (7).

2. Holding drivebelt (5) up, turn adjustable pulley flange (4) clockwise as far as possible by hand.

3. Turn adjustable pulley flange (4) on pulley flange (3) until there is no slack in drivebelt (5).

WARNING

1.

2.

3.

4.

8-68

Ensure fuel shutoff valve is OFF before turning over engine. Failure

to do this may result in injury to personnel.

Turn engine serveral revolutions, by turning crankshaft bolt (8), to equalize tension on both sides of

drivebelt (5).

Holding straight edge (6) along drivebelt (5), use 6-inch rule to push in center of drivebelt (5).

Correct drivebelt tension is 0.75 in. (1.905 cm) with firm finger grip on 6-inch rule.

Using pulley wrench and holding pulley flange (3), adjust drivebelt (5) tension:

a. Turn adjustable pulley flange (4) counterclockwise to loosen tension on drivebelt (5).

b. Turn adjustable pulley flange (4) clockwise to increase tension on dvebelt (5).

When drivebelt (5) tension is correct, install two new lockwashers (1) and screws (2) in adjustable

pulley flange (4).

Back to Top