TM-9-2320-361-20 - Page 687 of 1207

TM 9-2320-361-20

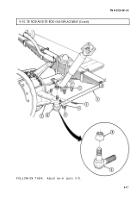

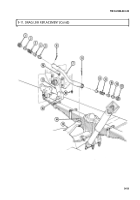

10-4. PINTLE HOOK MAINTENANCE

This task covers:

a. Pintle Hook Removal

d. Pintle Hook Latch Installation

b. Pintle Hook Latch Removal

e. Pintle Hook Installation

c. Cleaning and Inspection

INITIAL SETUP:

APPLICABLE MODELS

REFERENCES (TM)

All

LO 9-2320-209-12-1

MATERIALS/PARTS

TM 9-2320-361-10

TM 9-2320-361-20P

Two locknuts

Three cotter pins

EQUIPMENT CONDITION

Rags (Appendix C, Item 21)

Parking brake set (TM 9-2320-361-10).

Drycleaning solvent (Appendix C, Item 26)

GENERAL SAFETY INSTRUCTIONS

Keep fire extinguisher nearby when using

drycleaning solvent.

a. Pintle Hook Removal

1. Remove cotter pin (21) from pintle hook (14) and nut (1). Discard cotter pin (21).

2. Remove nut (1), washer (2), and pintle hook (14) from rear crossmember (4).

3. Remove two locknuts (20), inner bracket (3), two screws (18), and outer bracket (19) from rear

crossmember (4), Discard locknuts (20).

b. Pintle Hook Latch Removal

1. Remove cotter pin (16) from lock (11). Discard cotter pin (16).

2. Remove two grease fittings (13) and (5) from drive pin (12) and screw (6).

3. Remove cotter pin (10) from screw (6) and slotted nut (9). Discard cotter pin (10).

4. Remove slotted nut (9), screw (6), and lock (11) from pintle hook (14).

5. Remove drive pin (12), latch (7), and spring (8) from lock (11).

6. Inspect drivescrew (15) and chain (17) for damage. Replace drivescrew (15) or chain (17) if damaged.

c. Cleaning and Inspection

WARNING

Drycleaning solvent is flammable and will not be used near open

flame. Use only in well-ventilated places. Failure to do so may

result in injury to personnel.

1. Clean all parts with drycleaning solvent and dry with clean rag.

2. Inspect all parts for breaks and cracks. Replace all damaged parts.

3. Inspect spring (8) for breaks or collapsed coils. Replace if damaged.

4. Inspect for broken or missing chain (17), drivescrew (15), and cotter pin (16). Replace any broken or

missing parts.

5. Replace grease fittings (5) and (13) if broken or missing.

10-4

Back to Top