TM-9-2320-433-10 - Page 261 of 964

OPERATE CRANE - Continued

(2)

Ensure the hoist cable is vertical before starting the lift. Don't use crane to

drag load sideways.

(3)

Even if a hydraulic line is sheared or broken on the lift or extension

cylinder, the crane will still function sufficiently to get the load down.

(4)

Lift one load at a time. Do not lift two or more separately rigged loads at

one time, even if the loads are within the rated crane capacity.

(5)

When slings, ties, hooks, etc. are used, make certain they are correctly

positioned and secured before raising or lowering the loads.

(6)

If a tipping condition is encountered:

(a)

Start lowering the load with the hoist cable and retract or elevate the

boom to bring the load in.

(b)

Never lower or extend the boom as this will aggravate the tipping

condition.

(7)

When using the crane hoist, avoid sudden stops:

(a)

Increased loading will result.

(b)

Could cause tipping or a structural failure of crane to occur.

NOTE

In manual operation, the crane is operated by the control levers on the

main valve control unit.

2.

Manual (Vehicle Mounted Controls) Operation.

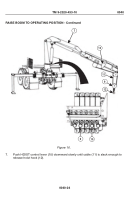

CAUTION

Whenever the boom is being extended, the HOIST control lever must

be pushed down to allow at least 1 ft. (0.3 m) of space between the

boom extension sheave at the end of the boom and the snatch block.

Failure to comply may result in damage to equipment.

NOTE

•

Crane control valves have variable speed capability. Moving a

lever slightly will cause slow movement of the crane function.

Moving the lever to its full travel will cause the crane function to

move faster.

•

If use of the remote-control unit is desired for operating the

crane, skip to Step (3).

TM 9-2320-433-10

0040

0040-27

Back to Top