TM-9-2330-202-13-P - Page 357 of 552

FIELD MAINTENANCE

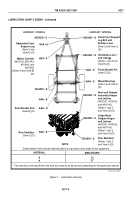

LUBRICATION INSTRUCTIONS

INITIAL SETUP:

Materials/Parts

Degreasing solvent

(WP

0114, Table 1, Item 9)

References

FM 9-207

References (cont.)

DA PAM 750-8

TM 9-214

WP

0054

WP

0063

GENERAL

NOTE

These instructions are MANDATORY.

1.

The M101 and M116 Series trailers must receive lubrication with approved lubricants at recommended intervals

in order to be mission-ready at all times.

2.

The KEY lists lubricants to be used in all temperature ranges and shows the intervals.

3.

The Lubrication Chart shows lubrication points, items to be lubricated, required lubricants, and recommended

intervals for lubrication. Any special lubricating instructions for specific components are contained in NOTES.

4.

Recommended intervals are based on normal conditions of operation; under extreme conditions, lubricants

should always be changed more frequently. When in doubt, notify your Supervisor.

LUBRICATION INSTRUCTIONS

1.

Keep all lubricants in a closed container and store in a clean, dry place away from extreme heat. Keep container

covers clean and do not allow dust, dirt, or other foreign material to mix with lubricants. Keep all lubrication

equipment clean and ready for use.

2.

Maintain a record of lubrication performed and report any problems noted during lubrication. Refer to

DA PAM 750-8 for maintenance forms and procedures for recording and reporting any findings.

WARNING

Wipe excess lubricant from the area of brake shoe linings to prevent grease from soaking the

linings. If brake shoe linings become soaked, have Field Maintenance replace them. Failure

to comply may cause brakes to malfunction resulting in death or injury to personnel. Seek

medical attention in the event of an injury.

3.

Keep all external parts not requiring lubrication free of lubricants. After lubrication, wipe off excess oil or grease

to prevent accumulation of foreign matter.

4.

After parts are cleaned, rinse and dry them thoroughly. Apply a light grade of oil to all polished metal surfaces

to prevent rusting.

TM 9-2330-202-13&P

0077

0077-1

Back to Top