TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 87 of 528

TM 9-2330-356-14

WARNING

Bonding of the semitrailer to aircraft and

grounding procedures per paragraph 2-8b

while refueling shall be mandatory, regard-

less of the amount of fuel to be dispensed,

due to the dangers of static electricity. Bond

the fuel nozzle ground wire to the aircraft be-

fore bringing nozzle In contact with the air-

craft.

(6) Unreel static reel cable and connect first to

grounding stud, then to aircraft.

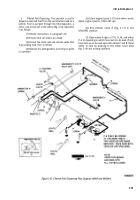

(7) Release lock (para 2-11) on the 2½-inch hose

reel and unreel to full length. Remove the dust capon the

bottom load adapter and connect single point nozzle to

bottom load adapter. Open single point nozzle by turning

handle on side of the nozzle.

(8) The defueling hose will be provided at

operation site. Remove dust cap from outlet C and

connect defueling hose to inlet. Nest connect the hose.

NOTE

Make sure valve E is closed and remains

closed during entire operation.

(9) Open valves A (para 2-11f), G, M, and R.

Reset the meter to zero by pushing in reset knob (fig. 2-15)

and turning clockwise.

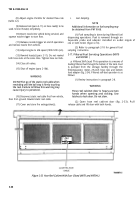

shut-off float. After about 20–25 seconds flow should stop

to indicate that the float is working properly (para 2-11g).

NOTE

When tank is full, flow should stop automati-

cally.

(13) Close precheck valve D to the CLOSED

position. Fuel flow will resume in about 20 seconds.

(14) At end of operation, release deadman control

S and adjust engine to idle speed (1000-1200 rpm).

Rewind the deadman control hose.

(15) First remove the defueling hose from aircraft,

then remove the hose ground wire. Disconnect the

defueling hose from inlet C. Replace the dust cap to outlet

c .

(16) Close the single point nozzle and disconnect

the nozzle from the bottom load adapter. Replace dust

caps on single point nozzle and bottom load adapter.

(17) Evacuate hose (para 2-14d)

(18) Rewind the 2-inch hose (para 2-11). Tighten

hose reel lock.

(19) Close all valves and shut off engine

(para 2-10d).

WARNING

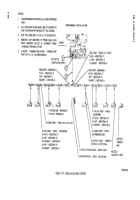

(10) Set engine throttle at desired flow rate

DO NOT let go of the static reel cable when

(table 2-2).

rewinding until the ball stop is firmly touching

the reel. Failure to follow this warning may

(11) Unreel deadman control S. Squeeze the

cause injury to personnel.

trigger on deadman control to start fuel flow. Meter inlet

pressure gage (fig. 2-15) should be indicating a minimum

of 25 psi. If a minimum of 25 psi is not indicated, shutdown

(20) Disconnect the ground connection first from

operation and contact unit maintenance.

the aircraft, then from the grounding stud. Rewind the

static reel cable.

WARNING

When filling tank by means of defueling, a test

of the precheck system is mandatory. If this

system is not functioning, stop all operations.

Determine the problem and have it corrected

by a qualified technician. Failure of automatic

shut-off to function may result in uncontrolled

fuel spillage and danger of fire and explosion.

(12) Shortly after flow has begun, turn precheck

valve D to (he OPEN position to precheck the automatic

WARNING

Hose reel cabinet door is heavy-use two

hands when opening and closing. Use

latches to lock door. Do not slam.

(21) Close hose reel cabinet door and latch it in

place.

(22) Store and cover fire extinguishers.

e.

Defueling Operation With 1½-inch Hose.

This

operation is used to remove fuel from an aircraft. The fuel

is pumped from the aircraft through a filter/separator, a

2-45

Back to Top