TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 82 of 528

TM 9-2330-356-14

Figure 2-36. Attaching Fuel Sampling Hose to Nozzle

(M970 and M970A1).

(4) When enough fuel is collected, unscrew fuel

sampling coupling from the adapter. Install cap on adapter

and put fuel sampling coupling in tool box.

b.

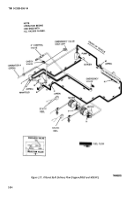

Aircraft Single Point Underwing Fuel Dispensing

Operation.

This operation is used to dispense metered fuel

from semitrailer to an aircraft through an underwing

connection. Fuel is pumped through the filter/separator, a

meter, and a hose reel to the aircraft (fig. 2-37). Operation

is as follows:

(1) Review instructions in paragraph 2-8.

WARNING

Hose reel cabinet door Is heavy-use two

hands when opening and closing. Use

latches to lock door. Do not slam.

(2) Open hose reel cabinet door. Pull release

cable and’ lift door with both hands.

(3) Ensure that all valves are closed.

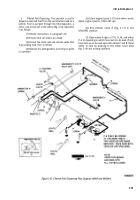

(4) Unreel the static reel cable and

first to grounding stud and then to aircraft.

connect it

(5) Remove fire extinguishers and take to point

of operation.

(6) Start engine (para 2-10) and when warm

adjust engine speed to 1000-1200 rpm.

(7) Open valves A (para 2-11f), H, M, and R.

Reset the meter to zero by pushing the meter reset knob

(fig. 2-15) and turning clockwise.

(8) Adjust engine throttle for desired flow rate

(table 2-2).

NOTE

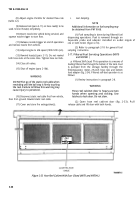

The breakaway fitting Is a safety feature on

hose reel for 2½-inch hose. It consists of a

breakaway coupling

installed between

2½-inch hose and outlet port of the hose reel.

Should aircraft be moved with single point

nozzle attached to wing, the coupling will

break apart as hose Is pulled tight against the

coupling, preventing damage to the aircraft.

For reassembly of breakaway fitting refer to

paragraph 3-13.

(9) Release lock (para 2-11) on the 2½-inch hose

reel. Unreel all 50-feet of 2½-inch hose to ensure that

breakaway feature will be operable.

WARNING

Bonding of the semitrailer to aircraft and

grounding procedures per paragraph 2-8b

while

refueling

shall

be mandatory,

regardless of the amount of fuel to be

dispensed, due to the dangers of static

electricity. Bond the fuel nozzle ground wire

to the aircraft before bringing nozzle in

contact with the aircraft.

(10) Attach single point nozzle (fig. 2-34) ground

wire to aircraft. Connect single point nozzle to adapter on

aircraft. Open nozzle by turning lever on side of nozzle.

(11) Unreel deadman control hose and activate

deadman control S by depressing control lever. Meter

inlet gage (fig. 2-15) should indicate a minimum of 25 psi.

Should gage not indicate a minimum of 25 psi, shut down

operation and contact unit maintenance.

(12) Release deadman control S at end of

operation,

and

adjust

engine to

idle

speed

(1000-1200 rpm). Rewind the deadman control hose.

(13) Close single point nozzle. First disconnect

single point nozzle from aircraft, then disconnect the

nozzle ground wire.

(14) Evacuate hose (para 2-14d).

(15) Rewind the 2½-inch hose (para 2-11).

Tighten hose reel lock.

(16) Close all valves and shut off engine

(para 2-10d).

2-40

Back to Top