TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 75 of 528

TM 9-2330-356-14

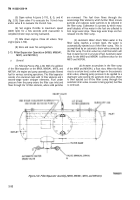

(b) As

water accumulates in the filter sump

of the M970 and M970A1, a float rises. When the float

rises a certain level, a valve will open in the automatic

drain valve, allowing pump pressure to be applied to a

diaphragm valve in the automatic drain valve and to the

pilot control on the 3-inch flow control valve. The pump

pressure opens the diaphragm valve and closes the 3-inch

flow control valve. Fuel flow is then shut off, preventing

dispensing of water-contaminated fuel, and the water in

the filter sump is passed through the automatic drain

valve. When the fuel flow is stopped by the closing of the

3-inch flow control valve, no coalescing occurs, and the

automatic water drain valve will continue passing water

until the float lowers. With the float in the lowered

position, the water drain valve closes, and the 3-inch

control valve opens. When this happens, pressure is

trapped in the line to the automatic drain valve diaphragm

and pilot control of the 3-inch control valve, preventing

resumption of fuel flow. To release the pressure, a bleed

line from the automatic drain valve diaphragm and pilot

control will relieve the pressure at the discharge side of

the water drain valve. Fuel flow will automatically start

again.

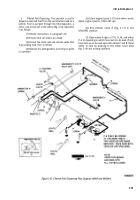

(3)

Cold Weather Draining.

During cold weather

operations, the accumulated water in the sump may

freeze. It is important that the manual drain N (fig. 2-30)

on the sump be opened after each operation to drain the

water accumulation. Be sure to close the drain valve after

draining.

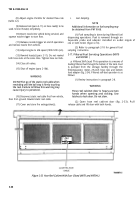

(4)

Go-No-Go Fuses.

Each of the 5 second-stage

coalescing elements is equipped with three Go-No-Go

fuses. These fuses are fuel contaminant monitoring

devices located “down-stream” of the second-stage. The

fuses restrict the fuel flow when small amounts of water

and solid contaminants are present in the fuel stream.

(a)

Each fuse consists of a perforated metal

tube filled with thin cellulose washers, except for a space

about l-inch long at one end. This space is for a plastic

piston forced against the washers by a spring. A plastic

nipple at the other end of the metal tube fits into an outlet

socket in the housing. Fuel flow is through the spirally

arranged perforations in the metal tube. The fuel must

flow through the very small passages (about 5 microns)

between the cellulose washers to reach the outlet.

(b)

As solid contaminants accumulate on

the outer surface of the stack of washers, resistance to fuel

flow increases. The resulting increased pressure further

compresses the washer stack. When the contaminant is

water, it is also absorbed by the cellulose washers, and the

action of the filter is similar.

(c)

When solid contaminants or water are

present, the compression of the washer stack continues

until fuel flow is stopped completely. But until this

happens, whatever fuel is passed through is still within the

specified standards for purity.

b.

Filter/Separator Gage. The

filter elements have a

limited capacity for retaining solids. As the solids content

increases, a pressure drop across the elements increases.

The pressure drop can be measured by a pressure gage

provided in the instrument panel (fig. 2-9). Operating

pressure readings should be taken and recorded at the first

day of operation and each day of operation thereafter. At

initial operation or with replacement elements, the

pressure gage reading should not exceed 3 psi. When the

pressure gage reading reaches 25 psi, the elements are

dirty and should be replaced. Notify unit maintenance

personnel when pressure reaches 25 psi.

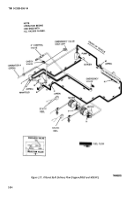

2-16. Filtered Fuel Servicing Operations (M969

and M969A1)

a.

Filtered Bulk Delivery.

This operation is to be used

when filtered fuel is required in the storage facility

(fig. 2-31). Fuel is pumped from the semitrailer tank

through the filter/separator to the storage facility.

Filtered bulk delivery operation is as follows:

(1) Review instructions in paragraph 2-8.

(2) Ensure that all valves are closed.

(3) Connect grounding wire to storage facility

and semitrailer (fig. 2-7). Remove 4-inch bulk fuel hose

(para 2-13) from hose trough and connect it to the

receiving facility. Remove dust cap from outlet B and

connect bulk fuel hose to outlet.

(4) Remove fire extinguishers and bring them to

the point of operation.

(5) Start engine (para 2-10) and when warm

adjust engine speed to 1000-1200 rpm.

(6)

(7)

(8)

(table 2-2).

(9)

Put selector valve E in UNLOAD position.

Open valves A (para 2-11f), B, H, M, and K.

Adjust engine throttle for desired flow rate

At end of operation, adjust engine to idle

speed (1000-1200 rpm).

(10) Close all valves.

(11) Remove all hoses and store in hose troughs.

Secure hose trough latches. Reinstall dust cover on outlet

B.

(12) Shut off engine (para 2-10d).

(13) Remove grounding wire.

(14) Cover and store fire extinguishers.

2-33

Back to Top