TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 66 of 528

TM 9-2330-356-14

(5)

Put selector valve E (fig. 2-11) in LOAD

position (M967, M967A1, M969, and M969A1).

(6)

Open emergency valve operator A (fig. 2-11

or 2-12) (para 2-11f).

(7)

Begin flow.

WARNING

When filling tank by means of bottom loading,

a test of the precheck system is mandatory. If

this system is not functioning, stop all

operations. Determine the problem and have

It corrected by a qualified technician. Failure

of automatic shut-off to function may result In

uncontrolled fuel spillage and danger of fire

and explosion.

(8)

After flow has begun, open valve D to

precheck the shut-off float (para 2-11g). If float is

functional, flow should stop after about 20-25 seconds.

(9)

Close valve D. Flow will resume in about 20

seconds.

NOTE

Be prepared to stop the fuel supply at the

loading facility in event of shut-off float

malfunction, if leaks are apparent, or other

unusual conditions are seen.

(10)

When tank is full, the flow should stop

automatically. Close all valves, replace all covers, and

disconnect the hoses.

(11)

(12)

(13)

Drain accumulated water (para 2-13d).

Remove grounding wires.

Store and cover fire extinguishers.

c.

Gravity Unload.

(1)

Review instructions in paragraph 2-8.

(2)

Ensure that all valves are closed.

(3)

Connect grounding wire to storage facility

and grounding stud (fig. 2-7) on top of semitrailer.

(4)

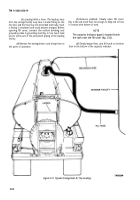

Remove 4-inch bulk delivery hose(s) from

trough (fig. 2-20) by disconnecting spring pins and turning

hose trough bars out of the way.

(5)

Remove dust cover from outlet B (figs. 2-23

and 2-11 or 2-12), and connect hose to outlet B and to

storage facility.

(6)

Remove fire extinguishers and bring to point

of operation.

(7)

Make sure valve E (fig. 2-11) (M967,

M967A1, M969, and M969A1) is in the UNLOAD

position.

(8)

Open valves A (para 2-11f), H, G, and B

(fig. 2-11 or 2-12) to begin flow.

(9)

At end of operation, close all valves.

Disconnect the hose and put it in hose trough; secure hose

trough latches. Reinstall dust cover on outlet B.

(10)

Drain accumulated water (para 2-13d).

(11)

Remove grounding wires.

(12) Store and cover fire extinguishers.

d.

Water Drain.

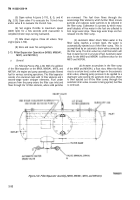

Accumulated water should be

drained from the system after each period of operation

(fig. 2-24).

(1)

Ensure that all valves are closed.

(2)

Put a container under manifold drain in

piping control cabinet. Open emergency valve operator A.

Slowly open valves H and J. Allow to drain until pure fuel

begins to flow. Close valves H and J, and emergency valve

operator A.

(3)

Drain the pilot lines on all models. Open

drain valves as indicated in figure 2-25. Allow to drain until

fuel begins to flow. Close drain valves.

(4)

On models M969, M969A1, M970, and

M970A1, also drain the filter/separator. Open valve M.

Put a container under valve N on bottom of

filter/separator. Slowly open valve N. Allow to drain until

fuel begins to flow. Close valves N and M.

2-24

Back to Top