TM-9-2350-311-10 - Page 442 of 775

TM 9-2350-311-10

3-6

ARMAMENT AND CAB MAINTENANCE — CONTINUED

3-6.3

Rammer Assembly

a. Adjustment

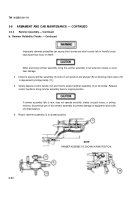

Do not spot paint bridge clamp or plunger as it could cause damage to equipment. Lubricate

rammer blocking valve plunger and roller (item 13, Appx G).

1

If tray (1) contacts rammer mounting bracket (2) refer to steps 2 and 3 to adjust position of rammer

mounting bracket.

2

With rammer assembly (3) in stowed position, adjust two cap screws (4) to provide a clearance of

approximately 1/4 inch (6.4 mm) between tray (1) and rammer mounting bracket (2).

3

Securely lock cap screws (4) in position with two hex nuts (5) and Iockwire (6).

NOTE

RAMMER ASSEMBLY IS SHOWN IN RAM POSITION.

3-42

Back to Top