TM-9-2350-311-10 - Page 435 of 775

TM 9--2350--311--10

Change 6

3--35

3--5

HULL MAINTENANCE PROCEDURES — CONTINUED

3--5.7

Maintenance of T--154 Track — Continued

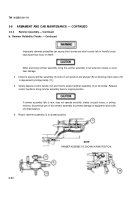

e. Connecting Track -- Continued

4

Install end connectors (2) until end connectors are flush with track link pins (6) on track shoe (3) by

tapping with hammer.

NOTE

A lubricant is applied to end connector bolts at the manufacturer. Any end connector bolt

torqued dry is incorrectly torqued (too LOW). If a bolt is removed and reinstalled, a new coating

of lube must be applied. Any oil or grease is acceptable.

5

Install end connector bolts (1) and tighten.

6

Mark replaced end connectors (2).

7

Move track so that end connectors (2) are at the 12 o’clock position (top) of idler wheel (8).

NOTE

Notify unit maintenance to torque end connector bolts (1) to 380-420 lb-ft (515-570 N

.

m).

6

7

1

2

3

1

3

8

8

Adjust track tension (para 3--5.5).

CAUTION

Hard pivot steers are unacceptable and may cause a track to be thrown.

9

Drive vehicle at a speed not to exceed 10 MPH for a short distance alternating right and left steers.

9.1

Move vehicle backward and forward several times on level ground. Moving forward, shift transmission

into neutral and coast to a stop without applying the brakes.

10

Stop vehicle and visually inspect for any end connectors (2) that may have shifted. If any end

connectors have shifted, reposition. Tighten end connector bolts (1) (steps 6 and 7) that have been

repositioned. Notify unit maintenance to torque bolts to 380--420 lb--ft (515--570 N

•

m) wet.

Back to Top