TM-9-2350-311-10 - Page 444 of 775

TM 9-2350-311-10

3-6

ARMAMENT AND CAB MAINTENANCE — CONTINUED

3-6.3

Rammer Assembly — Continued

b.

Rammer Reliability Checks — Continued

Improperly rammed projectiles can cause short rounds and short rounds fall on friendly forces

causing serious injury or death.

When exercising rammer assembly, bring the rammer assembly to full extension slowly to avoid

seal damage.

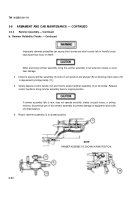

4

Check to assure rammer assembly (3) locks in ram position and plunger (9) on blocking check valve (10)

is depressed by bridge clamp (11).

5

Slowly depress control handle (12) and hold to extend rammer assembly (3) to full stroke. Release

control handle to bring rammer assembly back to original position.

If rammer assembly fails to ram, does not operate smoothly, makes unusual noises, or jerking

motions, discontinue use of the rammer assembly to prevent damage to equipment and notify

unit maintenance.

6

Return rammer assembly (3) to stowed position.

NOTE

RAMMER ASSEMBLY IS SHOWN IN RAM POSITION.

3-44

Back to Top