TM-9-2350-311-34-2 - Page 322 of 552

TM 9-2350-311-34-2

6-11 EQUILIBRATED ELEVATION MECHANISM ASSEMBLY - CONTINUED

d. Assembly - Continued

16

17

18

19

20

21

22

23

6-60

NOTE

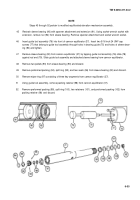

Steps 16 through 23 pertain to modified equilibrated elevation mechanism assembly.

Two different designs of seal rings are approved for use in the cannon equilibrator.

One of these designs is a closed seal and can be installed with either face to the pressurized

side of the cannon equilibrator.

The other approved seal design is “unidirectional” and has an open face on one side exposing

an o-ring “energizer.” This open face must be installed facing the pressurized side of the cannon

equilibrator to seal effectively.

Lubricate new preformed packing (94), new split ring (95), and two new seal rings (96) with hydraulic fluid

and install on sleeve bearing (90).

Install two new pellets (93) in sleeve bearing (90).

NOTE

Installation of key segments and sleeve bearing requires two people.

Install three key segments of wiper ring (97) in center groove (103) inside cannon equilibrator (37). Hold in

place until sleeve bearing (90) is installed.

Use seal inserter when installing sleeve bearing in cannon equilibrator to prevent damage to seals

on the front cylinder bearing when passing oil port.

Insert seal inserter (106) into port (not shown) on cannon equilibrator (37). Lubricate sleeve bearing (90)

with hydraulic fluid and carefully slide into front end of cannon equilibrator. Use guide tool assembly (not

shown) to push into position.

Remove seal inserter (106) and guide tool assembly (not shown).

Lubricate new preformed packing (99), new split ring (100), new preformed packing (102), and two new re-

tainers (101) with hydraulic fluid and install on packing retainer (98).

Use seal inserter when installing packing retainer in cannon equilibrator to prevent damage to seals

on the rear half when passing oil port.

Insert seal inserter (106) into port (not shown) on cannon equilibrator (37). Carefully slide packing retainer

(98) into cannon equilibrator and onto end of sleeve bearing (90) using spanner attachment (91).

Using spanner attachment (91) with extension, restrain sleeve bearing (90) to install and tighten nut (92) on

back of sleeve bearing. Torque nut to 80-100 Ib-ft (108-136 N·m). Remove spanner attachment.

Back to Top