TM-9-2350-358-BD - Page 283 of 343

TM 9-2350-358-BD

13-9.

COAXIAL CABLE REPAIR - CONTINUED

Option 2:

Using conductive materials.

Limitations:

None

Personnel/Time Required:

•

1 soldier

•

0.5 hour

Materials/Tools:

•

Tubular copper braid (scavenge from available source)

•

Conductive foil (gum wrappers, cigarette packages) (scavenge from available source)

•

Tape, pressure (aluminum) (found in M2/3 generic BDR kit, Section III, Appendix C)

•

Kitchen foil (scavenge from available source)

•

Tape, insulation, electrical (item 63, Appendix C)

Other Options:

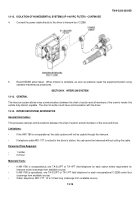

Remove one inch of insulation, unravel exposed shielding, and twist into pigtails.

Join the pigtails by splicing in a piece of

insulated wire.

Insulate the entire repair when using either method of repair.

Procedural Steps:

CAUTION

To prevent damage to the equipment ensure that this repair is sufficiently insulated to prevent the

center conductor from shorting to the shield.

1.

Remove 1/2-inch of insulation from the shielding and join the severed ends of the shielding together by wrapping a

conductive material over the repair.

Some suitable materials are tubular copper braid, metal gauze, conductive foil

from .gum wrappers. cigarette packages or common kitchen foil.

2.

Wrap the entire repaired area with electrical tape.

3.

Record BDAR action taken.

When mission is complete, as soon as practical, repair the equipment/system using

standard maintenance procedures.

13-15

Back to Top