TM-9-2815-202-34 - Page 591 of 670

TM9-2815-202-34

8-15.

FUEL FLOW TEST

e

This taskcovers: Testing

INITIAL SETUP

●

MODELS

TOOLS AND SPECIAL TOOLS

—

■

All

General mechanics tool kit (App B, Item 96)

Turbocharger inlet shield (App”B, Item 81)

Testing

NOTE

if necessary, adapt a fuel line

extension to the fuel return line to

reach container.

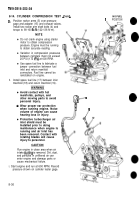

a. Attach a fuel return line (1) beyond

restricted fitting on engine.

b. HoId open end of fuel return line (1) in a

container (2).

WARNING

●

●

●

Avoid contact with hot

manifolds, pulleys, and

.

other moving parts to avoid

/)

personal injury.

\

Wear proper ear protection when running engine. Noise volume of

engine can cause hearing loss or injury.

Protective turbocharger air inlet shield must be installed prior to doing

maintenance when engine is running and air inlet has been removed.

Contact with rotating blades will cause injury to personnel.

CAUTION

Run engine in clean area when air intake ducting is removed. Dirt, dust, and particles

in unfiltered air can enter engine and damage parts or cause mechanical failure.

c. Start engine and run at 1200 RPM NO-LOAD. Using a stop watch (3), measure fuel flow from fuel

return line (1) for one minute. Minimum fuel return rate is 0.8 GPM.

o

d. Stop engine. Remove fuel line extension if adapted. Connect fuel return line (1).

END OF TASK

Change 1

8-39

Back to Top