TM-9-2815-220-24 - Page 293 of 1563

TM 9-2815-220-24

ENGINE RUN-IN

0044 00

WP 0044 00-7

RUN-IN (Continued)

3.

Run the engine at 675-725 rpm.

a.

Check for fuel and oil leaks.

Should leakage be detected, immediately shut off engine and

make repair.

b.

After 5 minutes of operation, check oil level and add sufficient amount of proper grade oil

to bring oil level to FULL mark on oil level gauge rod.

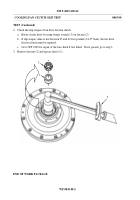

•

There are four key requirements that must be met to assure accurate reading of the oil level

gauge rod for during operation checks.

*

The oil temperature must be

U

less than

U

140 °F

(60 °C).

*

The engine must have been idling for at least 5 minutes.

*

The engine must be level and flat.

*

The correct side of the gauge rod must be read.

CORRECT SIDE OF GAUGE ROD FOR DURING CHECK

4. Stop engine.

5.

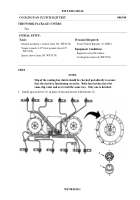

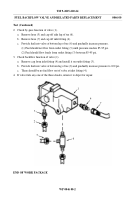

Install engine cooling fans.

a.

Remove cotter pin (4).

b.

Remove slotted nut (5).

c.

Remove flat washer (6).

d.

Remove spacer sleeve (8).

e.

Place fan (7) over shaft in place of

spacer.

f.

Secure with flat washer (6) and slotted

nut (5).

g.

Torque-tighten-nut (4) 600-625 inch-

pounds (68-71 N•m).

h.

Install new cotter pin (4) (item 53,

WP 0175).

ENG. IDLING RANGE

4

5

6

7

8

Back to Top