TM-9-2815-224-34-P - Page 287 of 554

TM 9-2815-224-34&P

Fuel Injector Maintenance Instructions (Cont)

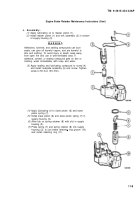

12-3. FUEL INJECTOR REPAIR.

This task covers:

a. Disassembly

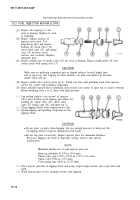

d. Needle Valve Tip Test

b. Cleaning/Inspection

e. Assembly

c. Needle Valve Lift Test

f. Follow-on Maintenance

INITIAL SETUP

Models

All

Test Equipment

Tension tester

Special Tools

Injector tip gage J5119

Rack tester kit J22396

Injector service kit J23435-02

Brass wire brush J7944

Reamer, injector J2 1089

Block set, lapping J22090-A

Polishing stick set J22964

Injector test kit J23010

Spray tip gage J9462-02

Supplies

Oil, fuel, diesel, Item 44, Appendix C

Methyl ethyl ketone, Item 42, Appendix C

Solvent, dry cleaning, Item 60, Appendix C

Lapping and grinding compound, Item 27,

Appendix C

Oil, test, fuel injector, Item 52, Appendix C

Compound, polishing Item 28, Appendix C

Caps, shipping and sealing, Item 11,

Appendix C

Ties, cable, plastic, Item 66, Appendix C

Personnel Required

MOS 63W, Vehicle wheel repairer

References

None

Equipment Condition

TM or Para

Condition Description

Fuel injector on clean work

surface.

Special Environmental Conditions

Work in a clean, well ventilated work area.

General Safety Instructions

WARNING

●

●

●

●

Fuel and test oil are very flammable and

can explode easily. To avoid serious injury

or death, keep fuel away from open fire

and keep fire extinguisher within easy

reach when working with fuel.

When working with fuel, post signs that

read “NO SMOKING WITHIN 50 FEET.”

When testing or adjusting fuel injectors, do

not place hands or arms in front of injector

spray tip.

Fuel spray from an injector has sufficient

penetrating power to puncture the flesh

and destroy tissue. Should fuel enter blood

stream, it can cause blood poisoning.

Level of

Maintenance

General Support

12-5

Back to Top