TM-9-2815-225-34-P - Page 192 of 736

TM 9-2815-225-34&P

0018 00

0018 00-6

PISTONS, CONNECTING RODS, AND BEARINGS (Contd)

CLEANING AND INSPECTION (Contd)

13.

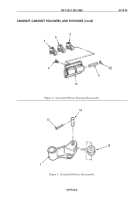

Inspect twelve connecting rod bolts (1) for bends, cracks, chipped or stripped teeth. Replace

connecting rod bolts (1) if damaged.

14.

Using a micrometer, inspect connecting rod bolt (1) pilot area outside diameter. Outside diameter

of pilot area should be 0.541–0.545 in. (13.74–13.84 mm). Replace any connecting rod bolt (1) if

outside diameter of pilot area exceeds 0.540 in. (13.72 mm).

15.

Using a micrometer, inspect connecting rod bolt (1) threaded area outside diameter. Outside

diameter of threaded area should be 0.6245–0.6250 in. (15.862–15.875 mm). Replace connecting

rod bolt (1) if outside diameter of threaded area exceeds 0.6242 in. (15.855 mm).

NOTE

Always replace connecting rod and connecting rod cap as a

matched set.

16.

Inspect connecting rod (2) and connecting rod cap (3) for nicks, dents, scratches, and gouges.

Replace connecting rod (2) and connecting rod cap (3) if any nicks, dents, scratches, or gouges are

deeper than 0.03125 in. (0.7938 mm).

NOTE

Perform steps 17 and 18 for connecting rod assembly inside

diameter measurement. Do not take measurement where

connecting rod and connecting rod cap meet, or an incorrect

measurement may result.

17.

Install connecting rod cap (3) on connecting rod (2) with two connecting rod bolts (4). Tighten bolts

(4) 140–150 lb-ft (190–203 N

•

m).

18.

Using inside micrometer, measure inside diameter of connecting rod (2) at connecting rod cap (3)

assembly at point A. Connecting rod inside diameter should be 3.3157–3.3167 in.

(8.4219–8.4244 cm). Replace connecting rod (2) and connecting rod cap (3) if not within

specifications.

NOTE

Perform steps 19 through 22 for connecting rod calibration.

19.

Install connecting rod (2) on connecting rod checking fixture.

20.

Using connecting rod checking fixture, check connecting rod (2) length. Replace connecting rod (2)

if longer than calibration rod on connecting rod checking fixture, or if more than 0.002 in.

(0.050 mm) shorter.

21.

Using connecting rod checking fixture, check alignment of connecting rod bores (5). Take first

measurement of connecting rod bores (5). Remove connecting rod (2) from connecting rod checking

fixture. Rotate connecting rod (2) 180°, install on connecting rod checking fixture, and take second

measurement. Replace connecting rod (2) if there is more than 0.010 in. (0.254 mm) difference in

measurements.

22.

Using feeler gauge, measure connecting rod (2) for twist between piston pin holding mandrel (6)

and dial indicator holding plate. Replace connecting rod (2) if clearance between piston pin holding

mandrel (6) and dial indicator holding plate is more than 0.020 in. (0.5078 mm).

Back to Top