TM-9-2815-225-34-P - Page 194 of 736

TM 9-2815-225-34&P

0018 00

0018 00-8

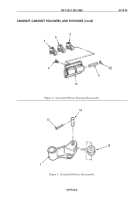

PISTONS, CONNECTING RODS, AND BEARINGS (Contd)

ASSEMBLY

NOTE

Apply lubricating oil to all parts before assembly.

1.

Align oil holes in new bushing (10) with oil holes in connecting rod (6). Using press and

connecting rod bushing driver, install new bushing (10) in connecting rod (6). Ensure that

0.125 in. (3.175 mm) diameter rod can pass easily through oil holes.

2.

Install one retaining ring (4) in piston (5).

WARNING

Wear rubber gloves when installing piston pin to prevent

burns from boiling hot water or hot piston. Failure to comply

may result in injury to personnel.

3.

Heat piston (5) to 210° F (98.9° C) for 15 minutes in water or oven.

CAUTION

Do not use hammer or any other tool to install piston pin.

Install piston pin by hand only. Failure to comply may result

in damage to piston.

4.

Position connecting rod (6) in piston (5) and install connecting rod (6) to piston (5) with piston

pin (3).

5.

Install retaining ring (4) in piston (5).

NOTE

If one or more four-ring-groove pistons are to be replaced,

replace all pistons. New replacement piston will have three

piston ring grooves instead of four. Never mismatch pistons.

If you are installing three-ring-groove piston, perform step 6.

If you are installing four-ring-groove piston, perform step 7.

6.

Using piston ring expander, install three new piston rings (13), (14), and (15) on piston (5) with

word “top” facing up. Start with new oil control ring (13) on bottom, new second compression ring

(14) in middle, and new first compression ring (15) on top.

7.

Using piston ring expander, install four new piston rings (11), (12), (1), and (2) on piston (5) with

word “top” facing up. Start with new oil control ring (11) on bottom, new intermediate

compression ring (12) second from bottom, new second compression ring (1) in middle, and a new

first compression ring (2) on top.

8.

Install two dowel pins (7) in connecting rod cap (8).

NOTE

Always replace connecting rod bearings as a set.

9.

Install new connecting rod bearings (9) in connecting rod (6) and connecting rod cap (8).

10.

Repeat steps 1 through 9 for all remaining piston (5), connecting rod (8), and bearing (7)

assemblies.

11.

For piston, connecting rod, and bearing installation, refer to WP 0042 00.

Back to Top