TM-9-2815-225-34-P - Page 200 of 736

TM 9-2815-225-34&P

0019 00

0019 00-4

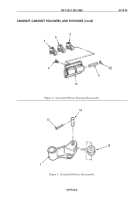

CAMSHAFT, CAMSHAFT FOLLOWERS, AND PUSH RODS (Contd)

CLEANING AND INSPECTION

1.

For general parts cleaning information, refer to CLEANING, WP 0051 00.

2.

For general parts inspection information, refer to INSPECTION, WP 0051 00.

NOTE

Replace any part that does not pass visual inspection or is

outside specified wear limits.

3.

Inspect camshaft gear (1) for cracks, chips, rounded or stripped teeth.

4.

Using micrometer or equivalent, measure camshaft bearing journals (6) outside diameter. Camshaft

bearing journals (6) outside diameter should be 2.496–2.497 in. (6.339–6.342 cm). Discard camshaft

(2) if camshaft bearing journals (6) outside diameter is 2.495 in. (6.337 cm) or smaller.

5.

Inspect camshaft follower housing (10) for cracks, chips, and breaks.

6.

Inspect camshaft follower housing (10) for sharp edges, nicks, or burrs. Camshaft follower housing

(10) should have a slight radius. Remove sharp edges, nicks, or burrs with 240-grit aluminum

oxide paper attached to a split rod and drill.

7.

Inspect cam follower bushing (11) on intake (7), injector (8), and exhaust cam followers (9) for

scratches, pitting, scoring and other damage. Discard intake (7), injector (8), and exhaust cam

followers (9) if cam follower bushing (11) is damaged.

NOTE

Cam follower bushing inside diameter must measure

0.7501–0.7511 in. (19.053–19.078 mm).

8.

Using micrometer, measure inside diameter of cam follower bushing (11). Discard intake (7),

injector (8), or exhaust cam followers (9) if cam follower bushing (11) diameter measures more

than 0.752 in. (19.101 mm).

9.

Inspect intake (7), injector (8), and exhaust cam follower levers (9) for cracks using magnetic

particle inspection (WP 0051 00). Discard intake (7), injector (8), or exhaust cam follower

levers (9) if any cracks are found.

10.

Inspect pushrod insert (13) for scoring, galling, pitting, and excessive wear.

11.

Inspect intake (3), injector (4), and exhaust pushrod (5) for bends or out-of-round. Discard intake

(3), injector (4), or exhaust pushrod (5) if bent or out-of-round is more than 0.035 in. (0.889 mm).

12.

Check pushrod insert (13) using ball end of intake (3), injector (4), and exhaust pushrods (5) as follows:

a.

Apply a coat of Prussian blue compound to ball end of intake (3), injector (4), and exhaust

pushrods (5).

b.

Install ball end of intake (3), injector (4), and exhaust pushrods (5) into pushrod insert (13)

and rotate 80°.

c.

Replace intake (7), injector (8), and exhaust cam followers (9) if pushrod insert (13) is

damaged or has less than 80% contact with ball end of intake (3), injector (4), and exhaust

pushrods (5).

13.

Inspect roller (12) for cracks, breaks, and other damage. Discard intake (7), injector (8), or

exhaust cam followers (9) if roller (12) is damaged.

NOTE

Intake and exhaust cam follower roller inside diameter must

measure 0.5005–0.5015 in. (12.713–12.738 mm). Discard intake

or exhaust cam followers if roller (12) is out-of-round. Discard

intake injector, or exhaust cam followers if inside diameter

measures more than 0.503 in. (12.776 mm).

Injector cam follower roller inside diameter must measure

0.703–0.704 in. (17.856–17.882 mm). Discard injector cam

follower if inside diameter measures more than 0.705 in.

(17.907 mm).

14.

Using small bore gauge, measure roller (12) inside diameter.

Back to Top