TM-9-2815-225-34-P - Page 204 of 736

TM 9-2815-225-34&P

0019 00

0019 00-8

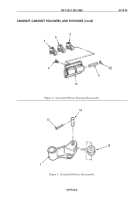

CAMSHAFT, CAMSHAFT FOLLOWERS, AND PUSH RODS (Contd)

ASSEMBLY

1.

Install roller pin (2) and roller (3) on intake cam follower (4).

2.

Using 0.006 in. (0.15 mm) feeler gauge between intake cam follower (4) and roller (3), install roller

pin (2) on intake cam follower (4) and roller (3). Secure roller pin (2) to intake cam follower (4)

with roll pin (1).

NOTE

All camshaft follower housings are assembled in the same

manner. Repeat step 3 for remaining cam follower housings.

Ensure injector cam follower is in center position and that cam

follower pushrod sockets are on the same side as dowel holes in

housing.

3.

Install two exhaust camshaft followers (6), injector camshaft followers (5), intake camshaft

followers (4), and camshaft follower shafts (8) on camshaft follower housing (9).

NOTE

Expansion plugs should be at least flush with edge of hole or

not more than 0.010 in. (0.254 mm) below edge of hole.

Apply light coat of cup plug sealant to expansion plug hole in

each end.

4.

Using press and mandrel, install two new expansion plugs (7) on ends of camshaft follower

housing (9).

5.

Install two screws (10) securing camshaft follower shaft (8) on camshaft follower housing (9).

6.

Install orifice plug (11) and keyway (14) on camshaft (15). Tighten orifice plug (11) 5–10 lb-ft

(7–13 N

•

m).

WARNING

Use insulated gloves when handling heated camshaft drive

gear. Failure to observe this warning may result in injury to

personnel.

CAUTION

Do not use cutting torch to heat camshaft gear; damage will

result.

7.

Heat camshaft gear (12) evenly in oven to 400º F (209° C).

8.

Using press, install hot camshaft gear (12), new thrust bearing (13), and keyway (14) on

camshaft (15).

Back to Top