TM-9-2990-206-34P - Page 20 of 85

Table 2-1. Troubleshooting - Continued.

(8)

(9)

(l0)

(11)

Apply equal pressure to the compressor wheel and turbine wheels

to move the turbine wheel shaft as far as possible away from

the indicator plunger. The indicator pointer should return to

zero.

Repeat steps (5) through (8) to verify the indicator reading.

If the maximum radial clearance is less than 0.003 inch

(0.076 mm) or greater than 0.006 inch (O. 152 mm), repair the

turbosupercharger. Refer to page 3-1.

If the maximum radial clearance is 0.003 inch (0.076 mm) to

0.006 inch (0.152 mm), proceed to b.

below.

b.

Check End Play.

(1)

(2)

(3)

(4)

(5)

(6)

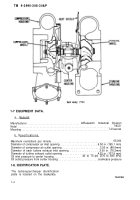

Clean the turbine wheel hub. Attach

a dial indicator (A) to the turbine

housing (or any flat surface) so that

the plunger rests on the turbine wheel

hub (B).

Push the turbine wheel down as far as

possible.

Set the dial indicator to zero.

Pull the turbine wheel up as far as

possible. Note end play on indicator

dial.

Repeat steps (2) through (4) to verify

the indicator reading.

If maximum end play is less than 0.004

inch (0.102 mm) or greater than 0.009

inch (0.229 mm), repair the turbo-

supercharger. Refer to page 3-1.

(7) If maximum end play is 0.004 inch

(0.102 mm) to 0.009 inch (0.229 mm),

and no other damage is evident:

(a) Using new gasket (C), install oil

drain tube (D).

(b) Secure oil drain tube with two

bolts and lockwashers (E).

Using 9/16 inch socket and

O to 300 pound-inch, 1/2

inch drive torque wrench,

tighten bolts to 275 pound-

inches (31 N-m).

(8) Clean unit and return to supply system.

TA007806

2-4

TM 9-2990-206-34&P

Back to Top