TM-9-6920-430-14 - Page 66 of 180

TM 9-6920-430-14

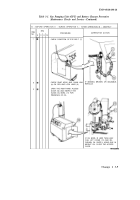

(1) Inspection for good conditions

●

Visual inspection for damage beyond safe or serviceable limits. Includes check of

flexible materials for hardness, cracks, or breaks.

(2)

(3)

(4)

Inspection for correct assembly and storage

• Visual inspection for improperly assembled or stowed items.

Inspection for security

• Visual inspection or check by hand, wrench, or pry bar for looseness.

Inspection for wear or corrosion

●

Visual inspection or check by hand for item worn or corroded beyond serviceable

limits. Also applicable to markings, data, caution plates and printed matter that is legible.:

NOTE

Where the instruction “tighten” appears in the procedure, it means tighten with the

proper tool, even if the item appears to be secure.

c. Column Entries Used in Preventive Maintenance Checks and Services

(1) Column 1, Item No.

Column 1 numbers the checks and services to be performed in

chronological order. This column will also be used as a source of item numbers for the “TM Number”

column on DA Form

2404,

Equipment Inspection and Maintenance worksheet, in recording results

of PMCS.

(2) Column 2, Interval.

Column 2 specifies the intervals at which the Preventive Mainte-

nance Checks and Services will be performed. The “B” interval requires the check to be performed

“Before Operation". The “D’ interval requires the check to be performed “During” power on. The

“A” interval requires the check to be performed “After Operation.” The “M” interval requires the

check to be performed “Monthly. ”

(3) Column 3, Procedures.

Column 3 provides the procedures for performing the check.

(4) Column 4, Corrective Action.

Column 4 contains the corrective action procedures.

3-6

Change 1

Back to Top