TM-9-6920-430-14 - Page 63 of 180

TM 9-6920-430-14

Section III. PREVENTIVE MAINTENANCE

CHECKS AND SERVICE

3-2. GENERAL.

Preventive maintenance checks and services you are authorized to

perform on the gas pumping unit and battery charger include inspection, cleaning,

painting and parts replacement in accordance with paragraphs 3-3 through 3-5. Upon

initial receipt and before use, check equipment for obvious damage and missing or broken

parts. If severe damage is evident, determine whether or not the required repairs can be

accomplished within your level of maintenance. Refer to Appendix E, List of Expendable

Supplies and Materials authorized for use when performing preventive maintenance on

either the GPU or battery charger.

3-3. GENERAL CLEANING INSTRUCTIONS.

Clean the exterior of the gas pumping

unit/battery charger and proof test equipment as necessary. If you cannot remove the dirt

with a dry, clean cloth (Item No. 9, Appendix E) or brush, wipe with a cloth moistened

with a little soapy water using general detergent (Item No. 4, Appendix E) (one packet per

3 gallons of water). Remember to wipe the cleaned area thoroughly dry. Do not use water

to clean connectors; use dry brush.

3-4. GENERAL PAINTING INSTRUCTIONS

a.

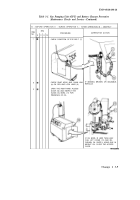

Touch up the battery charger and gas pumping unit if required. Figure 3-1 and 3-2

show the identification markings on the gas pumping unit and battery charger respectively.

Damaged markings called out in these illustrations should be corrected. Do not paint

identification plates.

b.

Lightly sand the areas to be painted using fine grit sandpaper (Item No. 7,

Appendix E). Clean with a soft cloth to remove sanding dust. Prime aluminum surfaces

with zinc chromate (Item No. 8, Appendix E). Allow to dry and paint with the color

specified in Figure 3-1, 3-2.

3-5. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

a.

At the specified intervals the applicable Preventive Maintenance Checks and

Services listed in tables 3-1 and 3-2 will be performed. The specified checks represent the

minimum number of essential checks. Before you begin the Preventive Maintenance

Checks and Services, keep in mind the following general information which is as

important as the specific checks.

(1) Before you operate, always keep in mind the CAUTIONS and WARNINGS.

Perform your Before (B) operation Preventive Maintenance Checks and Services.

(2) After you operate, be sure to perform your After (A) Preventive Maintenance

Checks and Services.

(3) Once a month, at the time decided upon by the squad leader, be sure to

perform your monthly (M) Preventive Maintenance Checks and Services.

(4) Other services and checks that must be provided during power on are listed in

operational procedures as required.

(5) If your equipment fails to operate, troubleshoot with proper equipment.

Report any deficiencies which cannot be corrected on DA Form 2404.

b.

Inspection is necessary to see if items are in good condition, correctly assembled or

stored, secured, not excessively worn or corroded, not leaking, and adequately lubricated.

Any or all of these checks that are pertinent to any item (including supporting, attaching,

or connecting members) will be performed automatically as a general procedure in

addition to any specific procedure given.

Change 3 3-3

Back to Top