MWO-5-2350-262-35-1 - Page 18 of 24

MWO 5-2350-262-35-1

Table 3-1.

MWO Parts List - Continued

Part Number

CAGE

NSN

Description

Qty

M45913/1-5CG5Z

81349

Nut, Self Locking

8

4FBTX-SS

30780

Adapter

2

2102-8-8

30780

Elbow, Pipe, 90 Degree

2

8-8 140339

81343

Elbow, Pipe, 45 Degree

3

5227606

19207

Reducer, Tube

2

7968260

19207

Handle, Fire Extinguisher

2*

F-2738-A01-3-1-24

81348

Seal, Antipilferage

2

*

If in serviceable condition, reuse these parts.

SECTION II. TOOLS REQUIRED

Tool Kit, General Mechanics: Automotive, NSN 5180-00-177-7033

SECTION III. REMOVAL PROCEDURES AND RIGHT SIDE BOTTLE HOLDER

SHIELD MODIFICATION FOR HALON (OLD PRODUCTION)

NOTE

Pay attention to all Notes, Cautions, and Warnings per TM 5-2350-262-20-1, Fixed Halon Fire

Extinguisher Tubes, Hose, and Fittings Replacement (Old Production) and TM 5-2350-262-

20-2, Muffler Shields Replacement.

CAUTION

Before removing the halon bottle, ensure control valve remains in reset position to avoid triggering

fire extinguisher.

Failure to comply may result in damage to equipment or injury to personnel.

Regardless of indication on pressure gauge i.e., safeguards must be in place even if pressure

gauge reads “0.0 psig”.

a.

Remove halon fire extinguisher tubes, hoses, and fittings per TM 5-2350-262-20-1.

b.

Remove halon fire extinguisher control valve, cable guides, and cable per TM 5-2350-262-20-1 and TM 5-

2350-262-20-2.

c.

Remove halon extinguisher, canisters, and clamps per TM 5-2350-262-20-1.

WARNING

When cutting and grinding CARC painted equipment, ensure proper ventilation and that

personnel wear appropriate protective equipment.

Dust from grinding CARC paint is to be

treated and disposed of as hazardous waste. Failure to comply may result in injury or death.

NOTE

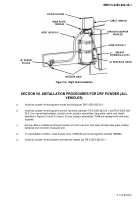

Steps d through f below apply to Figure 3-1.

d.

Using suitable aluminum cutting tool, cut right side fire extinguisher bottle holder shield from holder,

leaving 1.5 inches on each side (Figure 3-1).

e.

Using suitable aluminum grinder, smooth new edges and surfaces.

3-2

Back to Top