TB-9-2320-335-13-P - Page 23 of 680

TB 9-2320-335-13&P

2-1

Section I. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

The best way to maintain vehicles covered by this manual is to inspect them on a regular basis so minor

faults can be discovered and corrected before they result in serious damage, failure, or injury. All intervals

are based on normal operation. Hard time intervals may be shortened if lubricants are contaminated or if

you are operating the equipment under adverse conditions, including longer-than-usual operating hours.

Hard-time intervals may be extended during periods of low activity, though adequate preservation

precautions must be taken. This section contains systematic instructions of inspection, adjustment,

lubrication, and correction of vehicle components to avoid costly repairs or major breakdowns. This is

Preventive Maintenance Checks and Services (PMCS).

a.

Unit maintenance, assisted by operator/crew, will perform checks and services contained in table 2-1

at the following intervals:

(1) Semiannually.

Every 6 months or 3,000 miles (4,828 km), whichever comes first.

(2) Annually.

Every 12 months or 6,000 miles (9,656 km), whichever comes first.

(3) Biennially.

Every 24 months or 12,000 miles (19,310 km), whichever comes first.

b.

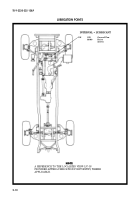

Refer to following steps when performing lubrication checks and services:

(1) Intervals.

Lubrication services coincide with the vehicle’s semiannual preventive maintenance

service. For this purpose, a 10% tolerance (variation) in specified lubrication point mileage is permissible.

Those vehicles not accumulating 1,000 mi (1,609 km) in a 6-month period will be lubricated at the time of

semiannual preventive maintenance service.

(2) For Operation of Equipment in Protracted Cold Temperatures Below -15°F (-26°C).

Remove lubricants prescribed in lubrication table for temperatures above -15°F (-26°C). Relubricate with

lubricants specified in lubrication table for temperatures below -15°F (-26°C). If OEA lubricant is required,

see the temperature ranges prescribed in the lubrication table. OEA lubricant is to be used in place of

OE/HDO 10 lubricant for all temperature ranges where OE/HDO 10 is specified in the lubrication table.

c.

Perform all semiannual inspections in addition to annual inspections at the time of the annual

inspection. Perform all annual and semiannual inspections in addition to biennial inspections at the time of

the biennial inspection.

All vehicle shortcomings will be reported on DA form 2404 (DA Pam 750-8), Equipment Inspection and

Maintenance Worksheet, immediately after the PMCS, and before taking corrective action. All vehicle

deficiencies will be reported in the equipment record.

2-3.

REPORTING REPAIRS

2-2. INTERVALS

2-1. GENERAL

CHAPTER 2

SERVICE AND TROUBLESHOOTING (UNIT) INSTRUCTIONS

Back to Top