TB-9-2320-335-13-P - Page 31 of 680

TB 9-2320-335-13&P

2-9

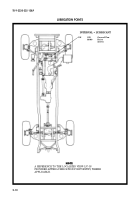

Section II. LUBRICATION INSTRUCTIONS

This appendix gives lubrication requirements for the REV vehicles which are the responsibility of the

operator/crew.

a. Maintaining Lubricant Levels.

Lubricant levels must be checked as specified in the PMCS and table

1-2, Lubrication. Steps must be taken to replenish and maintain lubricant levels.

WARNING

• Drycleaning solvent P-D-680 is TOXIC and flammable. Wear

protective goggles and gloves, use only in well-ventilated area,

avoid contact with skin, eyes, and clothes, and do not breathe

vapors. Keep away from heat and flame. Never smoke when

using solvent. The flashpoint for type I drycleaning solvent is

100°F (38°C), and for type II, is 138°F (59°C). Failure to comply

may result in injury or death to personnel.

• If personnel become dizzy while using cleaning solvent,

immediately get fresh air and medical help. If solvent contacts

skin or clothes, flush with cold water. If solvent contacts eyes,

immediately flush eyes with water and get medical attention.

b. Cleaning Fittings Before Lubrication.

Clean parts with drycleaning solvent P-D-680 or

equivalent. Dry before lubricating.

NOTE

Dotted arrow points indicate lubrication on both sides of the equipment.

c. Lubrication After Fording.

Following fording operation, lubricate all fittings below fording depth

and check submerged gear boxes for presence of water.

d. Lubrication After High-Pressure Washing.

After a thorough washing, lubricate all grease

fittings and oil can points outside and underneath vehicle.

e. Localized Views.

A reference to the appropriate localized view is given after most

lubrication entries.

2-7. GENERAL LUBRICATION REQUIREMENTS

2-6. SCOPE

Back to Top