TB-9-2510-251-24 - Page 66 of 212

TB 9-2510-251-24

1-56

3)

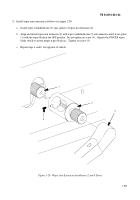

Install windshield armor (see figure 1-27).

a.

Apply Sealing compound to capscrews (2).

CAUTION

INTERIOR SURFACE OF WINDSHIELD GLASS IS

EASILY DAMAGED AND MUST BE PROTECTED

DURING DRILLING OPERATIONS.

b.

Position and align upper capping ring assembly (1) onto windshield frame pushed up until contacting

wiper pivot nuts, and transfer five hole locations to windshield frame.

Drill five each 25/64-inch holes in

windshield frame.

Install five short upset fasteners (4) in windshield frame.

c.

Install upper capping ring assembly (1) onto windshield frame and secure with five capscrews (2).

Do not

torque capscrews (2) at this time.

d.

Position and align center capping ring assembly (5) onto windshield frame and transfer three hole

locations to windshield frame.

Remove center capping ring assembly (5).

e.

Drill three each 25/64-inch holes in windshield frame. Install three short upset fasteners (4) in windshield

frame.

f.

Install center capping ring assembly (5) and secure with three capscrews (2).

Do not torque capscrews (2)

at this time.

g.

Position and align left capping ring assembly (3) onto windshield frame and transfer four hole locations to

windshield frame. Verify visually potential edge breakouts prior to drilling. Drill four each 25/64-inch

holes in windshield frame.

Install four short upset fasteners (4) in windshield frame.

h.

Install left capping ring assembly (3) onto windshield frame and secure with four capscrews (2).

Do not

torque capscrews (2) at this time.

i.

Position and align right capping ring assembly (3) onto windshield frame and transfer four hole locations

to windshield frame. Verify visually potential edge breakouts prior to drilling. Drill four each 25/64-inch

holes in windshield frame.

Install four short upset fasteners (4) in windshield frame.

j.

Install right capping ring assembly (3) onto windshield frame and secure with four capscrews (2).

Do not

torque capscrews (2) at this time.

k.

Torque capscrews (2) to 6 lb ft (8 N

•

m).

Back to Top