TB-9-2920-225-34-1 - Page 5 of 70

TB

9-2920-225-34-1

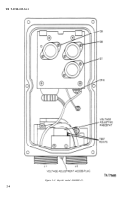

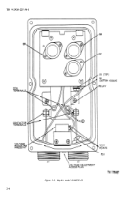

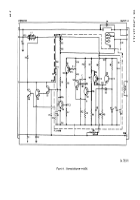

Figure 1–1.

100 AMP regulator.

1-4. Removal and Installation.

The regulator

1-5. Major Items Affected.

Because of the nu-

must be removed from the vehicle for testing and

merous vehicles affected, a listing of the vehicles

repair. The procedures given in this bulletin are

will not be supplied. Check the regulator’s NSN

for bench testing and repair only. Refer to the ap-

(2920-00-900-7993) or part number (10947439)

propriate vehicle manual for removal and instal-

in section IV of your vehicle’s repair parts manual

lation procedures for your particular vehicle.

for applicability.

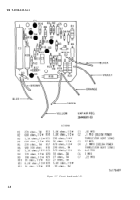

Section II. FUNDAMENTALS OF SOLID STATE COMPONENT CHECKOUT AND REPAIR

1-6. Introduction.

a.

Checkout and repair of solid

state voltage regulators involves techniques dif-

ferent from those employed with mechanical volt-

age regulators.

b.

Before attempting checkout and repair of

solid state voltage regulators, follow the instruc-

tions of paragraphs 1–7 and 1–8,

1-7. Meters.

a.

The type of meter used to check-

out solid state components is critical and should

be limited to quality meters such as the TS-352 or

the Simpson 260 multimeters, or their equivalent.

When using an ohmmeter with unknown technical

specifications or characteristics, the following

checks can be made to determine if the ohmmeter

scales will cause damage to low power transistors.

(1) Check the voltage across the ohmmeter

leads as the ranges are switched. No scale should

be used if the voltge exceeds 3 volts.

(2) If the instrument is a combination volt-

ohmmeter, the positive voltmeter lead may not

be the positive ohmmeter lead. The polarity of the

ohmmeter leads must be known. Polarity can be

determined by connecting the ohmmeter to a

voltmeter. If the voltmeter moves up scale the

ohmmeter has the same polarity as the voltmeter.

1-2

If the voltmeter attempts to move down scale the

ohmmeter leads have opposite polarity, e.g., TS–

352 multimeter. If necessary mark the ohmmeter

leads positive and negative for reference.

b.

The ohmmeter readings obtained when check-

ing semiconductor devices depends on the internal

makeup of the meter, scale used, type of transistor

and its temperature. Therefore, exact resistance

readings are seldom given. Readings are usually

referred to as low resistance, which is less than

20

ohms; and high resistance which is more than 200

ohms. Occasional failures may occur which can

be detected by these tests. If readings obtained are

doubtful or operation of the regulator is not

proper, replace the transistors.

1-8. DOs AND DON’Ts For Circuit Repair.

a.

DO—When replacing solid state circuit

boards, clip the connecting wires, leaving a small

portion of wire with insulation to act as a refer-

ence for connecting points on the replacement

board.

b.

DON’T—Attempt to interchange circuit

boards between regulator models.

c.

DO—Use high quality resin core solder of

60–40 tin lead composition.

Back to Top