TB-9-2920-225-34-1 - Page 7 of 70

TB 9-2920-225-34-1

CHAPTER 2

VAP-AIR MODELS

Section I. INTRODUCTION

2-1. Introduction.

Four models were produced by

Vap-Air, a division of Vapor Corporation.

Code Ident

80234 (FSCM)

Vapor Corp.

6420 W. Howard St.

Chicago, IL 60648

In 1978, the voltage regulator product line was

sold to DC Electronics Corporation.

Code Ident

34904 (FSCM)

DC Electronics Inc.

544 N. Highland Ave.

Aurora, IL 60506

TELEPHONE

AC 312844-5170

DC Electronics now provides parts and engineer-

ing support for all Vap-Air models. The Vap-Air

part numbers for each model are:

26440001-01

26440001–03

26440001-04

26440001-05

2-2. General Inspection.

This chapter applies to

all Vap-Air models.

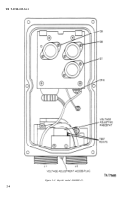

a. Regulator Box Assembly (external).

Check

for missing or stripped cover, connector mount,

retainer screws, and voltage adjustment access

plug.

Check connectors for signs of arcing, bent, or

pushed in pins, broken connectors, and thread

damage. Correct deficiencies by utilization of serv-

iceable components from unrepairables or requisi-

tioning components from the manufacturer.

(1) The pin receptacle (J2) is P/N 7064706

FSCM 19207 or MS3102A28-22P FSCM 96906

per MIL-C-5015.

(2) The socket receptacle (Jl) is P/N 7064-

706 FSCM 19207, an Army number for which

there is no equivalent NSN number. An assembly

is available from Bendix.

CODE IDENT 77820

(FSCM)

Bendix Corp.

The Electrical Components

Div.

Sherman Ave.

Sidney, NY 13838

It should be ordered as part number 60–42228-

10S; it will arrive as a complete assembly with

the shell marked 8701337.

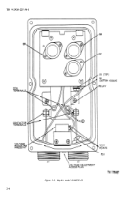

b. Regulator Box Assemblly (internal).

If water

leakage or corrosion is detected, it is possible that

extensive damage has been done and the regulator

cannot be easily repaired. Components should be

performance tested and retained if acceptable.

Check for disconnected or burnt wires, missing

components,

and replace repair as necessary.

Carefully remove the transistor mounting plate,

noting the position of the screws, washers and

rubber insulators. Visually inspect the circuit

board for burnt components. Replace the circuit

board through cannibalization if burnt compo-

nents are found. Carefully reinstall the transistor

mounting plate.

c. Regulator Verification Check.

After perform-

ing the above inspection, if the regulator appears

to be in good condition, check its performance on

a test stand. If the regulator fails this check, pro-

ceed to the following component tests.

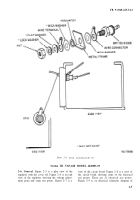

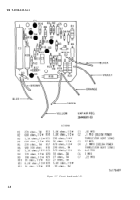

2-3. Bench Testing. Figures 2–1 and 2–2 show the

method for testing NPN transistors; these figures

apply to all models in this chapter. If the original

transistors are replaced with substitute part num-

bers, the repaired regulators should be carefully

tested to ensure proper operation.

2-1

Back to Top