TB-9-2920-225-34-1 - Page 6 of 70

TB 9-2920-225-34-1

d.

DO—Use a 60W AC or DC soldering iron.

Solid state components are easily damaged by ex-

cessive heat.

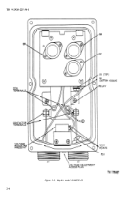

e. DON’T—Allow wires to become pinched be-

tweencovers, heat sinks, circuit boards, etc.

f.

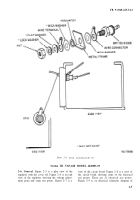

DON’T—Use a screwdriver to pry up transis-

tors during removal. The mica washer between the

transistor and the circuit board or heat sink is thin

and can be easily damaged.

g.

DON’T—Drop transistors since they are

easily damaged. If a transistor is dropped it should

be checked before being installed in the circuit.

h.

DO—Check transistor insulating washers

and replace if cracked, broken, or missing. Coat

washers with insulation compound (silicone) per

MIL-S-8660, NSN 6850–00–880–7616.

i.

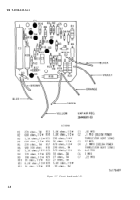

DO—After repair, remove all excess solder.

Check for loose wires, screws, and washers which

could cause short circuits and burnouts when

power is applied to the regulator.

j.

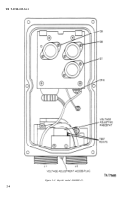

DO—Check the regulator cover seal, replace

if cracked or missing. Coat the seal with insula-

tion compound (silicone) per MIL-S-8660, NSN

6850-00–880–7616.

k.

DO—Apply adhesive 8040–877–9872 to the

adjustment access plug or screw.

.

1-3

Back to Top