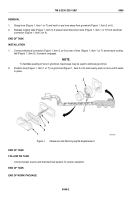

TM-5-2330-325-13-P - Page 210 of 648

RECEPTACLE REPAIR

1.

Remove nut (Figure 6, Item 1) and grommet (Figure 6, Item 2) from connector (Figure 6, Item 5).

2.

Remove terminals (Figure 6, Item 4) from grommet (Figure 6, Item 2).

NOTE

Only unsolder leads that need to be repaired.

3.

Remove terminals (Figure 6, Item 4) from wire leads (Figure 6, Item 3). Discard terminal (Figure 6, Item 4).

CAUTION

Insert terminals in proper location according to chart in (Figure 6). Failure to comply may

result in damage to, or destruction of, equipment or mission.

4.

Install wire lead (Figure 6, Item 3) through grommet (Figure 6, Item 2).

5.

Heat the solder well in terminal (Figure 6, Item 4). While solder is hot, insert wire lead (Figure 6, Item 3) into

terminal (Figure 6, Item 4).

6.

Install terminals (Figure 6, Item 4) in grommet (Figure 6, Item 2).

7.

Install grommet (Figure 6, Item 2) in connector (Figure 6, Item 5) with nut (Figure 6, Item 1).

8.

Connect intervehicular connector and check for proper operation (WP 0005).

A

B

C

D

E

F

N

M

H

J

K

L

TERMINAL

DESIGNATOR

A

24-484

H

BLANK

B

22-461

J

22-480

C

24-483

K

BLANK

D

90

L

BLANK

E

21-489

M

BLANK

F

23

N

BLANK

TERMINAL

DESIGNATOR

TERMINAL

DESIGNATOR

CIRCUIT

NO.

466_0129

2

1

3

4

5

Figure 6.

Receptacle Repair.

END OF TASK

END OF WORK PACKAGE

TM 5-2330-325-13&P

0043

0043-8

Back to Top