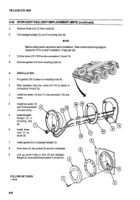

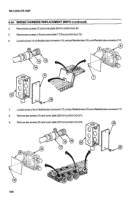

TM-5-2330-378-14-P - Page 151 of 524

TM5-2330-378-14&P

4-34. WIRINGHARNESSREPLACEMENT(M870)

ThisTaskCovers:

a.

Removal

b.

Installation

Initial Setup:

Tools/Test Equipment:-

- Grease (item 6, Appendix F)

• Common no. 1 tool set (Item 6, Appendix B)

- Solder (item 18, Appendix F)

• Tool kit, general mechanic's:

automotive

- Tape, insulation, electrical (item 22, Appendix F)

(item 7, Appendix 6)

Materials/Parts:

Equipment Conditions:

• Alcohol, denatured (Item 1, Appendix F)

- Semitrailer unloaded (para 2-12).

• Brush, acid swabbing (Item 2, Appendix F)

• Flux, solder (Item 5, Appendix F)

Personnel Required:

Two

a.

REMOVAL

WARNING

Disconnect

all outside

power before

performing

any maintenance

on the electrical

system.

Failure

to do so could

result In serious

injury or death.

NOTE

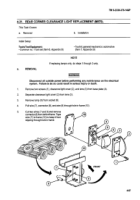

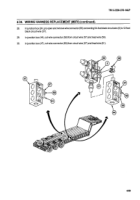

All circuit wires in the wiring harness are replaced the same way. This procedure is

for the black electric circuit for the service lights.

Refer to electrical wiring diagram

(Appendix

K) for correct color code and routing for replacement

of other circuits. See

Appendix G forwire

lengths of circuit being replaced.

This procedure requires one

54-foot wire, one 14-foot wire, one 112-footwire, and four 11.5-foot wires.

1.

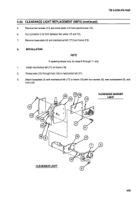

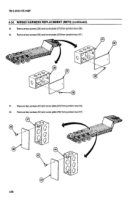

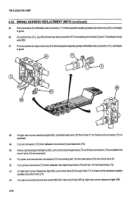

Remove six screws (1) from voltage reduction box (2).

2.

Remove box cover (3) from voltage reduction box (2).

3.

Remove black terminal wire screw (4) and 54-foot black circuit wire (5) from junction block (6).

2

10 0

0

5

4

4-63

Back to Top