TM-5-2330-378-14-P - Page 195 of 524

TIVI5-2330-378-14&P

4-49, SLACK ADJUSTERTEST.

ThisTaskCovers:

OperationalCheck

InitialSetup:

Tools/TestEquipment:

-Wheelschocked(pare2-10).

- Too] kit, general mechanic's:

automotive

- Brakes released (refer to operator's manual for

(item 7, Appendix B)

towing vehicle).

Equipment Conditions:

Personnel Required:

Two

- Semitrailer coupled to truck tractor (para 2-10).

OPERATIONAL

CHECK

NOTE

Considerable torque is required to rotate manual adjustment hex counterclockwise.

The required torque may be as high as 70 ft-lb (95 N-m).

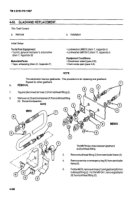

a.

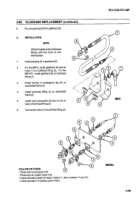

Rotate manual adjustment

hex (1) counterclockwise

approximately

one-half to oneturn,

b.

Using a straightedge, scribe a line across manual adjustment hex (1) head and slack adjuster (2) body.

C.

While assistant applies and completely

releases service brakes several times,

observe manual adjustment hex (1) and

scribed

line.

Manual adjustment hex

should

rotate

clockwise

during

the

application

and remain stationary during

release;

no counterclockwise

rotation

should beobserved.

NOTE

The amount of clockwise rotation (ad-

justment)will

decrease progressively

as service orspring brake nears proper

2

adjustment.

t

STRAIGHTEDGE

1

2

d.

If slack adjusterfails

to perform as de-

SCRIBE

scribed, replace it (para 4-48).

SCRIBED

MARKS

FOLLOW-ONTASKS:

Adjust brakes (para 4-47).

4-107

Back to Top