TM-5-2330-378-14-P - Page 203 of 524

TM 5-2330-378-14&P

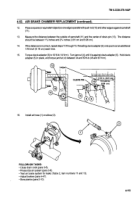

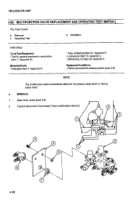

4-53. SPRINGBRAKECHAMBERREPLACEMENT(continued).

b.

INSTALLATION

NOTE

Wrap threaded ends of all brass fittings with two turns of antiseizing tape.

1

Install two elbows (2) on spring brake chamber (3).

2.

Install spring brake chamber (3) on axle mounting bracket (9) using two new lockwashers (8) and nuts (7).

Hand-tighten

nuts.

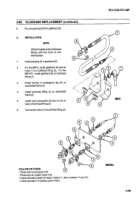

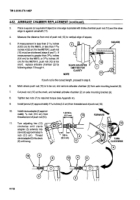

3.

Place a square (or equivalent object) so oneedge is parallelwith brake chamberpush rod (10) andtheother

edge is against camshaft (11).

4.

Measure the distance from end of push rod (110)to vertical edge of the square.

5.

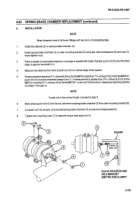

If measurement

is lessthan

21'/16

inches

(6.83 cm)forthe

M870

or lessthan

1II/le inches

(4.92 cm)forthe

M870AI,

push rod (10) must be shortened (steps 6 and 7). If measurement

is greater than 3

25/32

inches (9.6 cm) for the

M870 or more than 3

15/16

inches (10 cm)forthe

M870Al

, push rod (1O)istooshort;

replace spring brake chamber

(3) (steps 1 through 4).

NOTE

If push rod is the correct length, proceed to step 8.

6.

Mark where push rod (10) is to be cut, and remove spring brake chamber (3) from axle mounting bracket (9).

7.

Cut push rod (10) at mark, and reinstall spring brake chamber (3) on axle mounting bracket (9).

8.

Tighten two mounting nuts (7) to required torque (see appendix H).

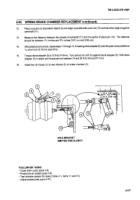

3

SQUARE

3

1-15116In.

9

(4.92

CM) -

10

8

7

11

SLACK

ADJUSTER

AND

AXLE

BRACKET

OMITTED

FOR

CLARITY

4-115

Back to Top