TM-5-2330-378-14-P - Page 207 of 524

TM 5-2330-378-14&P

4-54. RELAY EMERGENCYVALVE REPLACEMENT,OPERATINGTEST,AND LEAKAGE

TEST (continued).

b.

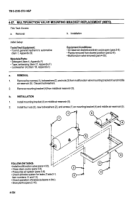

INSTALLATION

NOTE

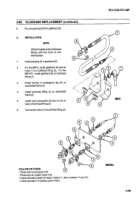

Before installing fittings into valve or tank, wrap fitting threads with two turns of

antiseizing

tape.

1

Install relay emergency valve (2) on rear air reservoir tank (3).

2.

Connect

four air

hoses (1) to relay emergency valve (2).

3.

Close drain cocks (pare 3-8).

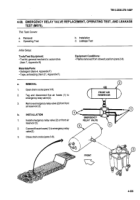

C.

OPERATING

TEST

1 .

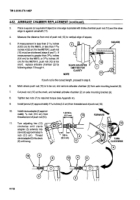

With gladhands

connected to towing vehicle, apply brakes. Check to see that brakes of all semitrailer

wheels

apply properly.

2.

Release brakes. Check to see that each brake releases properly.

3.

With brake system fully pressurized, close shutoff cock on emergency line in towing vehicle. Disconnect

gladhands tagged EMERGENCY from towing vehicle. Make sure semitrailer brakes apply automatically.

4.

Connect gladhands tagged EMERGENCY to towing vehicle. Open shutoff valve cock in towing vehicle.

Check to see that brakes release automatically.

d.

LEAKAGE TEST

1.

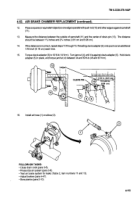

With air system connected, apply a solution of detergent (item 4, Appendix F) and water to flanges holding

diaphragm in service brake chamberand to gladhands tagged SERVICE. No leakage ispermitted. Tightennuts

on flanges and coupling on gladhands as required.

2.

With brake system fully pressurized, close shutoff cock on emergency hose in towing vehicle. Disconnect

gladhandstagged EMERGENCY from towing vehicle. Make sure semitrailer brakes apply automatically. Coat

relay emergency valve exhaust port with a solution of detergent (item 4, Appendix F) and water.

3.

Leakage must not exceed a one-inch bubble in three seconds. If excess leakage is found, replace relay

emergencyvalve (subparas4-64a and4-54b).

FOLLOW-ON TASKS:

- None

4-119

Back to Top