TM-5-2330-378-14-P - Page 211 of 524

TM 5-2330-378-14&P

4-56.

MULTIFUNCTION

VALVE

REPLACEMENT

AND OPERATING

TEST (M870A1)

(continued).

3.

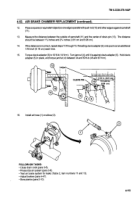

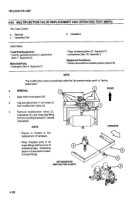

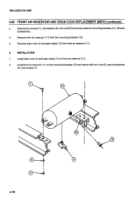

Hold multifunction valve (2) and remove two screws (3) and locknuts (4) from mounting plate (5).

4.

Remove multifunction valve (2) from cross tube fitting (6) and mounting plate (5).

5.

Remove lockwasher (7) from multifunction valve (2). Discard lockwasher.

b.

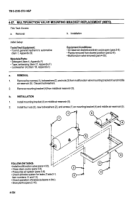

INSTALLATION

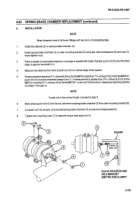

NOTE

Wrap threaded ends of all brass fittings with two turns of antiseizing

tape.

1 .

Install new lockwasher(7) and mounting plate (5) on multifunction valve (2).

2.

Install multifunction valve (2) and mounting plate (5) on cross tube fitting (6).

3.

Secure multifunction valve (2) and mounting plate (5) to frame with two locknuts (4) and screws (3).

4.

Connect 10 air hoses (1) to multifunction valve (2).

5.

Close drain cocks (pare 3-8).

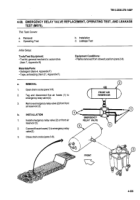

C.

OPERATING

TEST

WARNING

Wear

protective

goggles

when

opening

air reservoir

drain

cocks.

Avoid

contact

with

the

air stream.

1

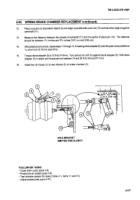

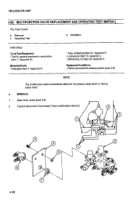

Pressurize

semitrailer air system (para 3-8). Shut off towing vehicle engine. The tires on the front and middle

axles of semitrailer

should lock. Open drain cock on front air reservoir.

2.

After air system is bled down, tires on front and middle axles should remain locked. Coat front reservoir drain

cock with a solution of detergent (Item 4, Appendix

F) and water.

3.

Leakage at open front reservoirdrain

cock should not exceed a one-inch (2.5 cm) bubble in five seconds. Ifexcess

leakage is found, replace multifunction

valve (subparas 4-56a and 4-56b).

4.

Close drain cock.

5.

Repeat steps 1 through 4 for drain cock on middle air reservoir.

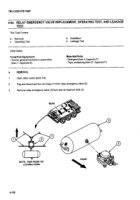

FOLLOW-ON

TASKS:

• Stow planks (pare 2-10).

• Check airbrake system for leaks (Table 2-1, item numbers 11 and 13).

• Check operation of brakes (para 4-54c).

4-123

Back to Top