TM-5-2330-378-14-P - Page 214 of 524

TM 5-2330-378-14&P

4-58.

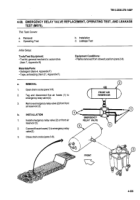

EMERGENCY RELAY VALVE REPLACEMENT, OPERATING TEST, AND LEAKAGE

TEST (M870) (continued).

c.

OPERATING

TEST

1.

With gladhands

connected

to towing vehicle, apply brakes. Check to see that brakes of all semitrailer

wheels

apply properly.

2.

Release brakes.

Check to see that each brake releases properly.

3.

With brake system fully pressurized,

close shutoff cock on emergency hose in towing vehicle.

Disconnect

gladhands tagged EMERGENCY

from towing vehicle.

Make sure semitrailer brakes apply automatically.

4.

Connect gladhands tagged EMERGENCY.

Open shutoff valve cock in towing vehicle.

Check to see that

brakes release automatically.

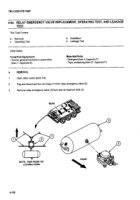

d.

LEAKAGE TEST

1 .

With air system connected,

apply a solution of detergent (Item 4, Appendix F) and water to flanges holding

diaphragm

inspring brake chamber, and to gladhandstagged

SERVICE.

No leakage is permitted. Tightennuts

on flanges and coupling on gladhands

as required.

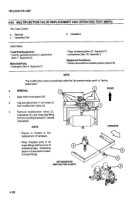

2.

With brake system fully pressurized,

close shutoff cock on emergency

hose in towing vehicle.

Disconnectglad

hands tagged EMERGENCY

from towing vehicle.

Make sure semitrailer brakes apply automatically.

Coat

emergency

relay valve exhaust port and multifunction valve exhaust portwith

a solution of detergent (Item 4,

Appendix F) and water.

3.

Leakage must not exceed a one-inch (2.5 cm) bubble in three seconds.

If excess leakage is found, replace

emergency relayvalve (para 4-58) or multifunction valve (para 4-55).

FOLLOW-ON TASKS:

- Stow planks (para 2-10).

4-126

Back to Top