TM-5-2330-378-14-P - Page 265 of 524

TM 5-2330-378-14&P

SectionII AXLEMAINTENANCE

Paragraph

Page

Number

ParagraphTitle

Number

5-2

General

.......................................................................................................................................

5.3

5-3

Middle Axle Replacement (M870) .

..............................................................................................

5-3

5-4

Middle Axle Replacement (M870A1) .

..........................................................................................

5-9

5-5

Front and Rear Axle Replacement (M870) .

.................................................................................

5-15

5-6

Front and Rear Axle Replacement (M870A1) .

............................................................................

5-18

5-7

Equalizing Beam Replacement (M870)

.......................................................................................

5-22

5-8

Equalizing Beam Replacement (M870AI)

..................................................................................

5-26

5-9

Trunnion Tube and Bracket Replacement (M870)

......................................................................

5-30

5-10

Trunnion Tube Replacement (M870A1)

......................................................................................

5-32

5-2.

GENERAL

This section provides information for performing

Direct Support level axle repairs on the M870 and M870AI

semitrailers.

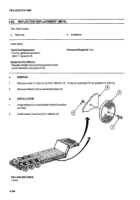

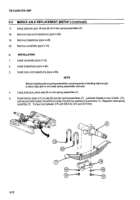

5-3.

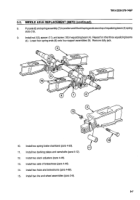

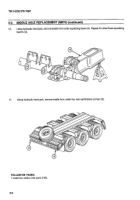

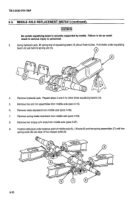

MIDDLE AXLE REPLACEMENT (M870).

This Task Covers:

a.

Removal

b.

Installation

Initial Setup.,

Tools/Test Equipment:

Equipment Conditions:

• Field maintenance too[ set (item 4, Appendix B)

Both radius rods removed (para 5-26).

• Tool kit, general mechanic's:

automotive

(item 7, Appendix B)

Personnel Required:

Three

• rrestle (6) (item 1, Appendix B)

MaterialslParts:

Self-locking nut (Item 36, Appendix 1)

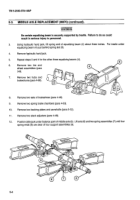

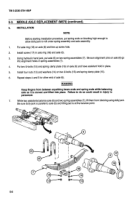

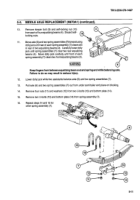

REMOVAL

3

NOTE

For secure placement of jacks, it

is

recommended

that

this

procedure

be performed on hard

floor surface.

1 .

Loosen, but do not remove, 10 lugnuts (1)

3

on tire and wheel assembly (2).

2.

Using hydraulic

hand jack, raise two rear

2

1

semitrailer corners (3) 32 inches (81 cm).

Place trestles under corners.

5-3

Back to Top