TM-5-2330-378-14-P - Page 294 of 524

TM5-2330-378-14&P

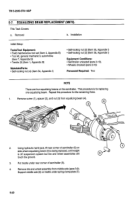

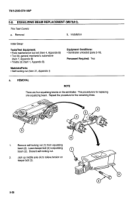

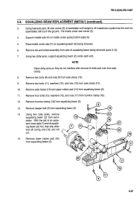

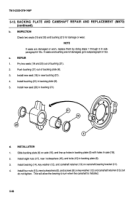

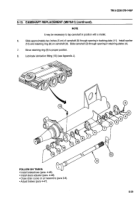

5-10. TRUNNIONTUBE REPLACEMENT(M870A1).

ThisTaskCovers:

a.

Removal

b.

Installation

Initial Setup:

Tools/Test Equipment:

Equipment Conditions:

• Field maintenance tool set (item 4, Appendix 13)

Tire and wheel assemblies removed (para 3-10).

• Tool kit, general mechanic's:

automotive

(Item 7, Appendix B)

Personnel Required:

Two

*Trestle (2) (Item 1, Appendix 13)

Materials/Parts:

• Grease (item 6, Appendix F)

• Self-locking nut (4) (item 34, Appendix 1)

a.

REMOVAL

NOTE

There

are two trunnion

tubes

on the semitrailer.

They are located

behind

the front

axle and in front of the rear axle, and run parallel to the axles. This procedure is for

replacement

of one trunnion tube.

Repeat the procedure for the other one.

1

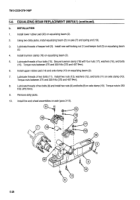

Using hydraulic jack, lift two rear corners (1) of semitrailer until weight is off suspension system but tire and

rim assemblies still touch the ground. Put trestles under rear corners (1).

2.

Using dolly jack, support equalizing beam (2) under trunnion tube (3), but do not lift. Repeat for equalizing

beam (2) at other end of trunnion tube (3).

3.

Remove four bolts (4), washers (5), and self-locking nuts (6) from trunnion clamp (7). Repeat for othertrunnion

clamp (7). Discard self-locking nuts.

4.

Remove two trunnion clamps (7) from two equalizing beams (2).

5.

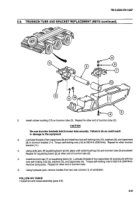

Using dolly jack, lower equalizing beam (2) until clear of trunnion tube (3). Repeat for equalizing beam (2) at

other end of trunnion tube (3).

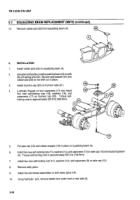

6.

Remove two bolts (8), washers (9), and nuts (10) from trunnion bracket (11). Repeat for other trunnion bracket

(11).

7.

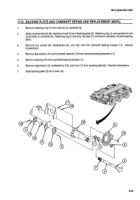

Remove two washers (12) and rubber bushing (13) from each side of trunnion tube (3). Mark washers to aid

in returning them to their proper location.

5-32

Back to Top