TM-5-2330-378-14-P - Page 324 of 524

TIVI5-2330-378-14&P

5-27.

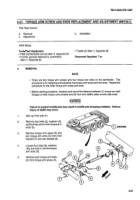

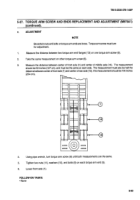

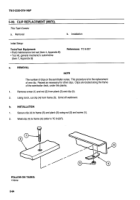

TORQUE ARM SCREW AND ENDS REPLACEMENT AND ADJUSTMENT (M870A1)

(continued).

b.

INSTALLATION

1.

Screw two torque arm ends (5) on torque arm screw (6) three turns each.

2.

While assistant holds torque arm ends (5), turn torque arm screw (6) with pipe wrench until distance between

two torque arm end flanges (13) is the same as measurement taken before start of procedure.

3.

Tighten two nuts (11), washers (10), and bolts (9) on each torque arm end (5).

4.

Install one torque arm end (5) in front bracket (7). Secure with locknut (4), washer (3), and bolt (2).

5.

Install othertorque armend (5) in rearbracket (8). Lubricate threads of bolt (2) and install locknut(4), washer

(3), and bolt(2)on rearbracket (8). Torque locknut (4)to 600ft-lb (814 N-m). If locknut (4)cannotbe reached,

torque bolt (2) to 840 ft-lb (1140 N-m).

NOTE

It may be necessary to adjust torque arm screw with pipe wrench.

2

6

2

11

10

8

12

3

4

7

4

3

5-62

Back to Top